There are two main types of rope: braided and twisted, each with its own advantages and disadvantages in terms of strength and use. Let's find out about 2 types of rope with Siam Brothers Vietnam in the article below!

Twisted rope

The rope is made up of tightly twisted fibers that form the rope's structure. In fact, there are several levels of twisting that need to be performed before the rope is ready for use. First, the fibers from any material used to make the rope – such as nylon – are twisted together to form strands called twisted fibers. These twisted fibers are much stronger than individual fibers, but they are not yet a rope. To create the rope, typically three strands are twisted together, and the end result of this twisting process is a rope that is ready for various applications.

One of the major advantages of twisted rope is its lower cost compared to braided rope. Since the production process for twisted rope is simpler, you'll find that the cost of twisted rope is lower for most twisted rope products. Using twisted rope for splicing is the preferred choice due to its applicability. Depending on the user's purpose, it should be noted that the strands of the rope may come apart over time.

Braided rope

The difference between braided and twisted rope lies in the technique of twisting or braiding the rope. Among the various types of braids used to make rope are double braids, solid braids, and hollow braids. A quick glance at the surface of a rope is enough to easily tell whether the product is made by braiding or twisting.

In many aspects, braided rope is the complete opposite of twisted rope; braided rope can perform well in areas where twisted rope is not applicable. Braided rope usually offers good flexibility, while many twisted ropes feel stiff and are difficult to maneuver. More importantly, braided rope is often much stronger than twisted rope. Many people also tend to prefer the feel of braided rope over twisted rope, although this largely depends on the user's needs.

Therefore, braided rope is an excellent choice for various situations. But it is not without its drawbacks. While twisted rope is the perfect choice for splicing applications, the opposite is true for braided rope. Splicing braided rope is a challenging task, so if the user frequently needs to splice rope, they should avoid using braided rope. Additionally, when the user requires a rope with good elasticity, braided rope is not the right choice.

Construction:

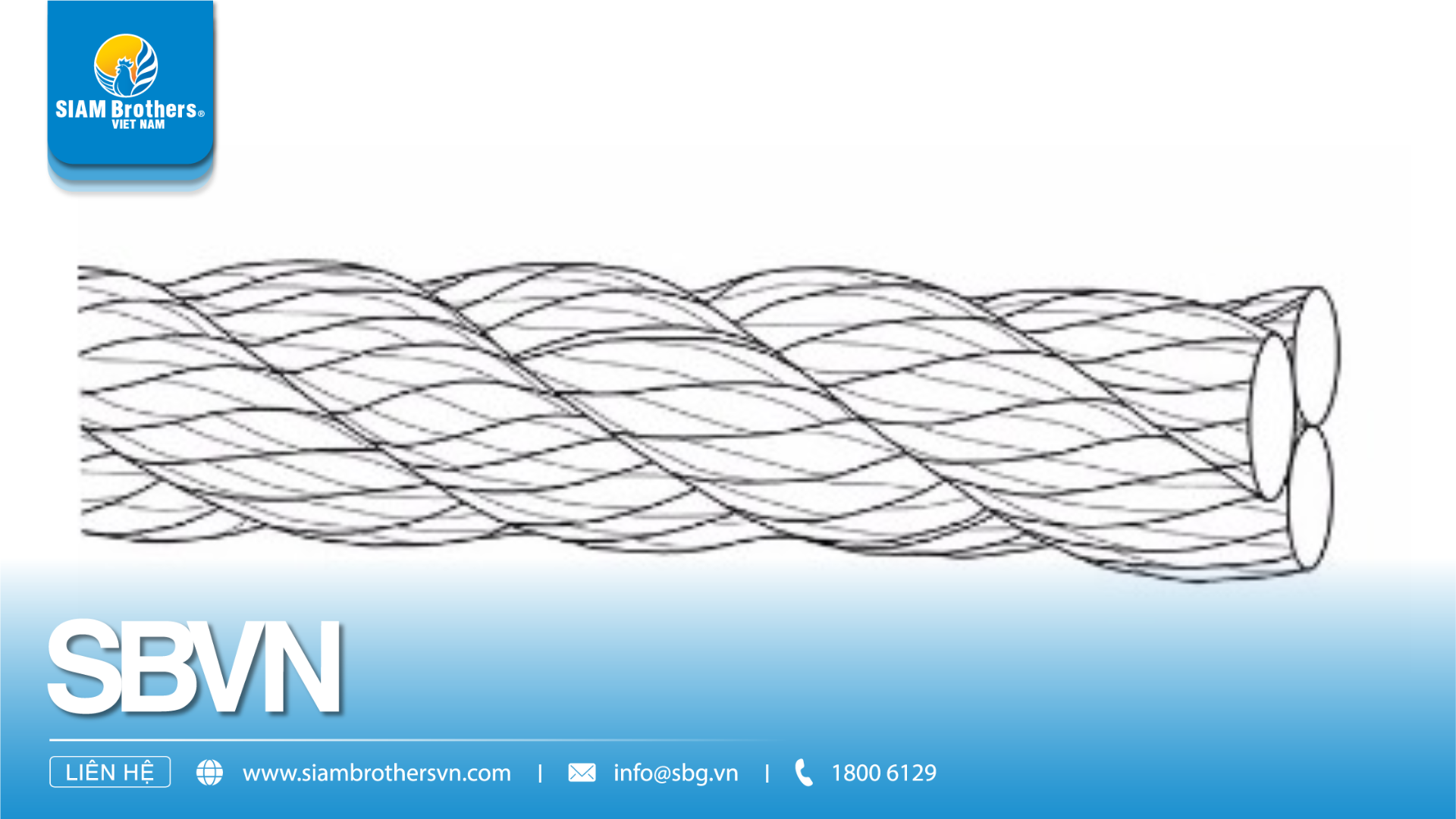

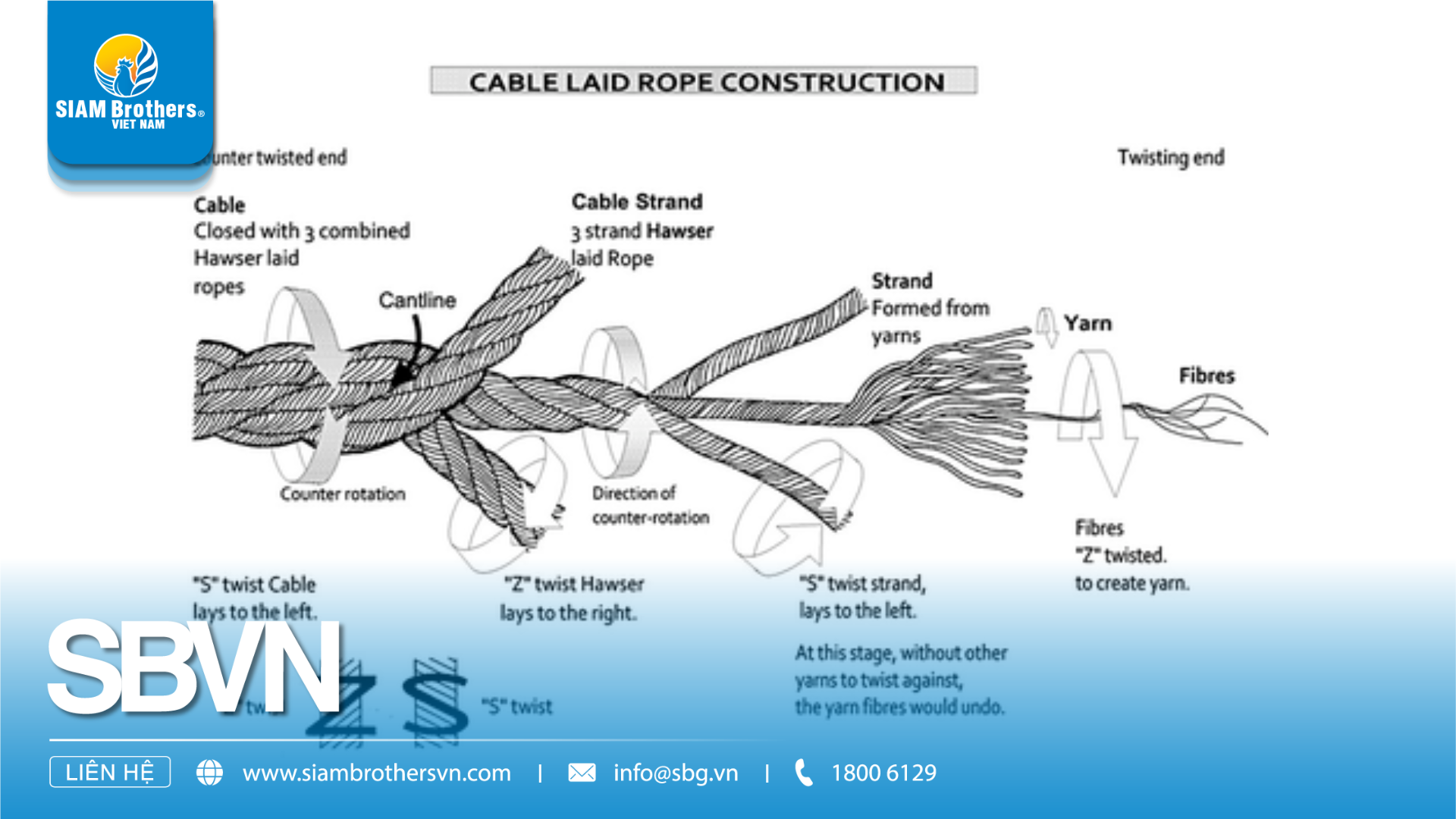

1. Twisted Rope:

Cre: shipsofscale

Made by twisting three or more strands together in a spiral pattern, creating a helical structure.

The strands are typically twisted in the opposite direction of the overall twist to maintain the rope’s integrity.

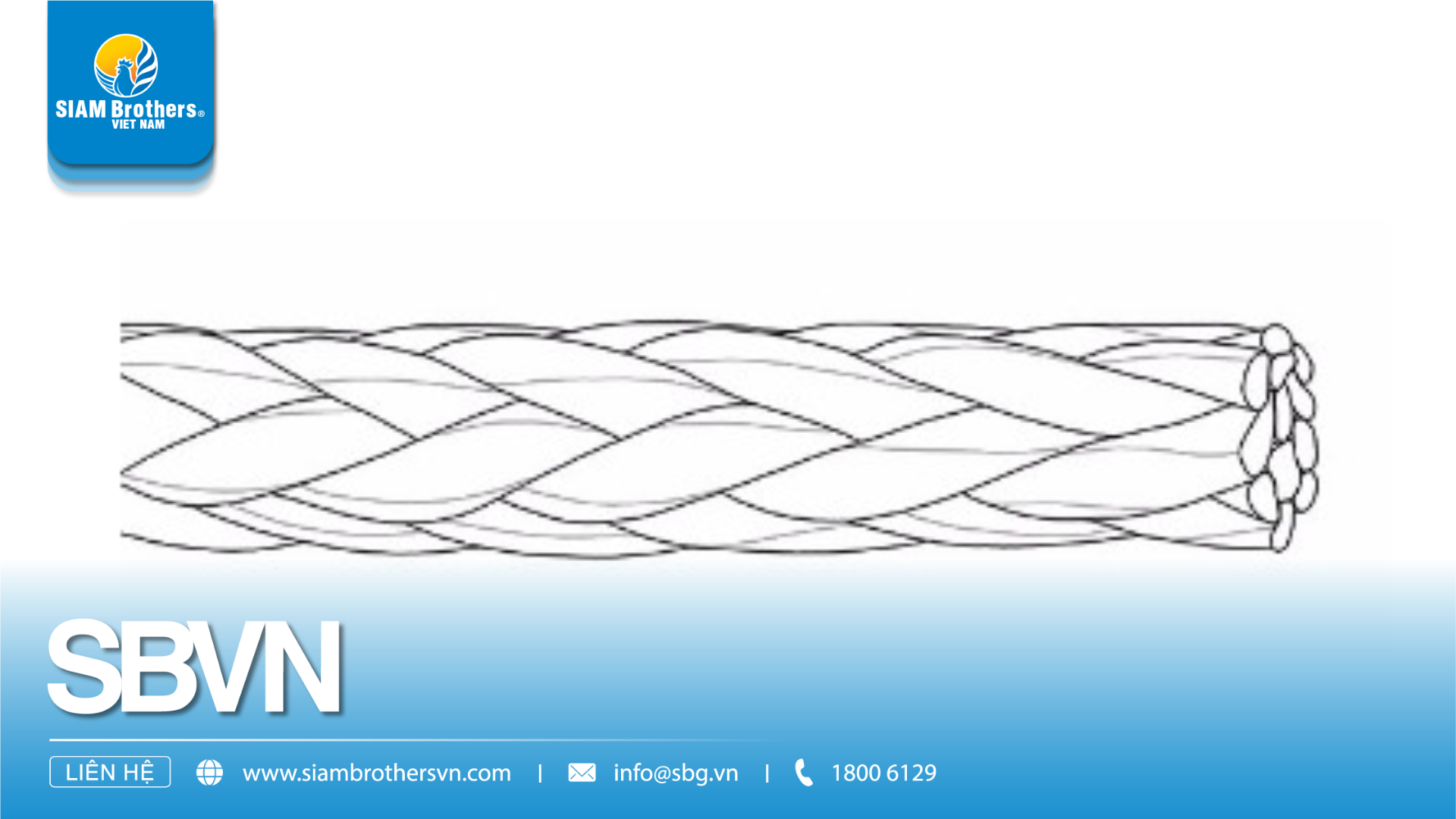

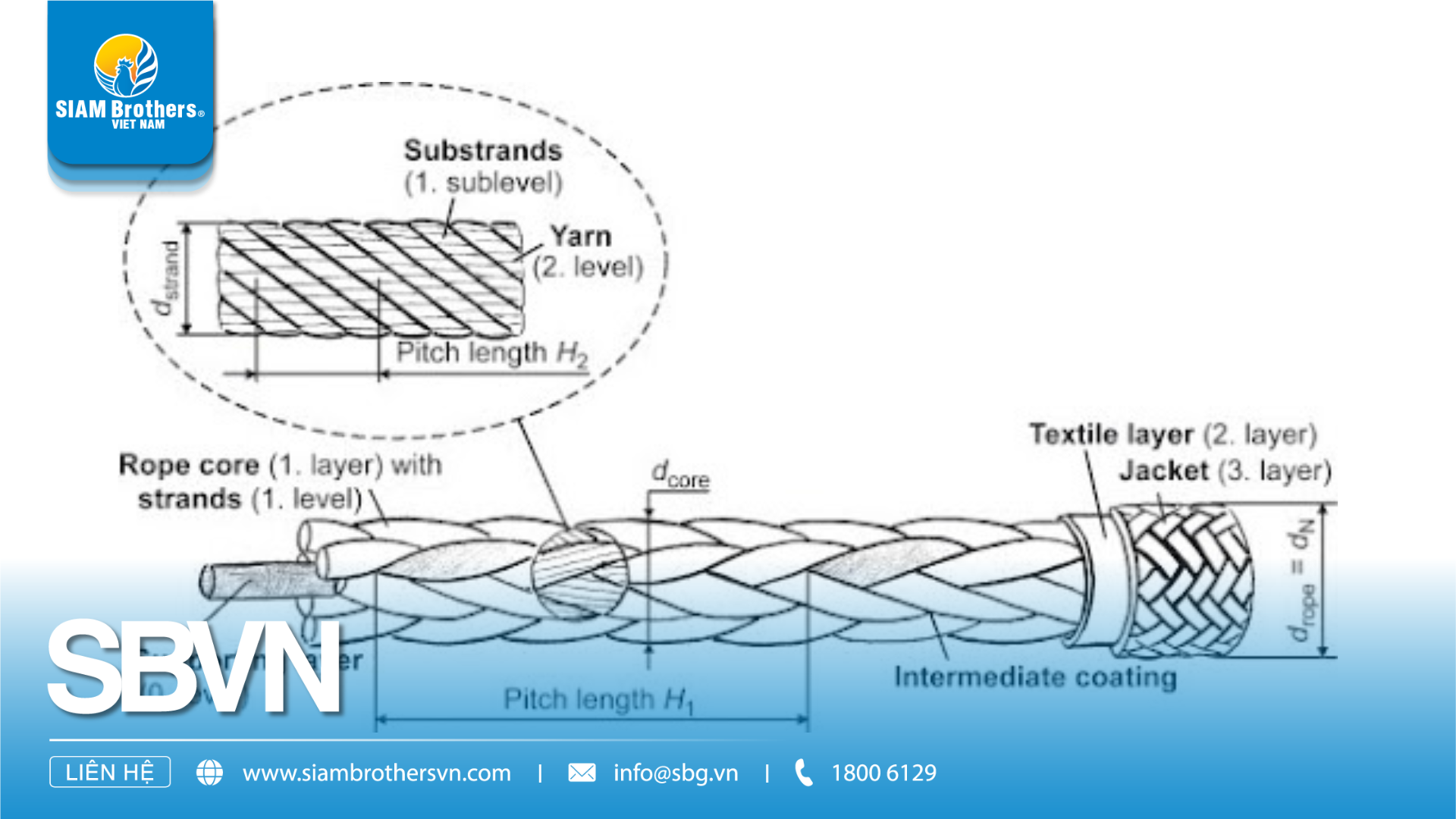

2. Braided Rope:

Cre: sciencedirect

Constructed by interweaving multiple strands in a crisscross pattern, resulting in a smooth, tubular appearance.

There are various types of braided ropes, including single braid (also called solid braid) and double braid, which features an inner core surrounded by a braided outer sheath.

This table provides an overview of the key characteristics of both types of ropes, helping you choose based on specific needs.

| Criteria | Twisted Rope | Braided Rope | ||

| Strength | Lower strength due to looser structure, prone to unraveling if cut. | Higher strength due to tightly interwoven structure, less prone to twisting under load. | ||

| Flexibility |

|

Flexible and offers better handling, smoother texture, and resistance to twisting. But hard to splice. | ||

| Typical Uses | Commonly used in climbing, mooring, and decorative purposes. | Ideal for applications requiring strength and smooth handling, such as sailing, towing, and industrial settings | ||

| Appearance | Traditional, rugged look with visible spirals. | Smooth and round appearance, often considered more aesthetically pleasing. |

Depending on the intended use, each type of rope has its own advantages and specific applications. Twisted rope, with its loose and flexible structure, is well-suited for applications requiring high flexibility and ease of splicing, such as climbing, mooring, or decorative purposes. On the other hand, braided rope, with its tight and durable construction, is ideal for applications requiring strength and smooth handling, such as sailing, towing, and in industrial settings. Therefore, choosing between twisted and braided rope should be based on the specific needs and requirements of the task or activity you are performing.

If you are looking for a manufacturer of rope, Siam Brothers Vietnam is the leading rope manufacturer in Vietnam established on 18/07/1995 with 100% capital investment from Thailand. Our main products are PP (polypropylene) rope, PE (polyethylene) rope, PET (polyester) rope, hay baler twine, and pp/pe yarn…with a wide range of applications including fishing, maritime transportation, industrial, agricultural, decoration…With 60 years of experience in manufacturing and trading as a rope supplier, the quality of Siam Brothers Vietnam products has been strongly trusted by the domestic and international markets for many years.

Contact us:

Address: 5th floor, VRG Building, 177 Hai Ba Trung Str., Vo Thi Sau Ward, Disc. 12, Ho Chi Minh City, Vietnam

Tel: (+84) 28 38 912 889

Hotline: 1800 6129

Website: siambrothersvn.com

Fanpage: facebook.com/siambrothersvn

Email: info@sbg.vn

Youtube: youtube.com/@siambrothersvietnam1728

Twitter: twitter.com/sbvnjsc

OA Zalo: zalo.me/1402339229697925373

App SBVN ID:

CHPlay: https://bit.ly/SBVNID-Android

Appstore: https://bit.ly/SBVNID-iOS