Cage farming in aquaculture is a method of cultivating and harvesting various aquatic species in a water environment enclosed by cage structures, typically constructed from materials such as bamboo, steel, or composite plastics. This method is commonly employed in the cultivation of fish, shrimp, and other seafood. Let's explore the popular types of aquaculture cages in Vietnam currently and how to choose the most suitable ones.

Detail

The cage section is made of nylon netting, preferably Polyethylene (PE) without knots (immovable mesh) or can also be replaced with Polyamide. The cage dimensions are typically Length 4m x Width 3m x Depth 2m or 4 x 2.5 x 2 (m). The netting type is woven 210/14 – 210/16 (coarse 210, twisted by 14-16 fibers into netting strands). The mesh size varies depending on the size of the cultured fish and to prevent floating feed from escaping the cage, as indicated in the table below:

| Fish Sizes (cm) | Cage Mesh Sizes 2a (cm) |

|---|---|

| 5 - 10 | 1,0 |

| 10 - 15 | 1,5 |

| 15 - 20 | 2,0 |

| 20 - 30 | 2,5 - 3,0 |

| 30 - 50 | 3,0 - 5,0 |

| > 50 | 6,0 |

The frame section should be constructed with durable and weather-resistant wood, capable of withstanding sunlight, rain, saltwater, and barnacle adhesion without being easily damaged over a relatively long farming period. Sturdy wood types such as Sao, Vên Vên, Căm Xe are recommended. The surface of the frame is made of wooden bars with openings for feeding, inspection, and fish harvesting. The sides of the frame are assembled with slats allowing a 1-1.5cm gap with vertical supports. The front of the frame is made of galvanized mesh with a mesh size of 1.5 x 1.5 (cm).

The floating section is assembled using barrels, bamboo, PVC, or styrofoam covered with waterproof fabric. To anchor the cage, anchor hooks are used, typically with four hooks and nylon ropes with a diameter of 2-3 (cm) and lengths of 30-50m to secure the cage.

Aquaculture cages with wooden and galvanized steel frame nets are commonly used for farming export-oriented fish such as catfish and basa, with a total combined area of about 1000m3. They are usually cultivated in areas sheltered from strong winds and waves, near the coast.

Cages made of wooden and galvanized steel frame nets are cost-effective, with easily accessible materials that do not require advanced technical skills. The lifespan of these cages is typically 3-5 years, making them suitable for novice fishermen due to their low cost, simplicity, and suitability for coastal and calm lake environments.

The cage section is made of nylon netting, preferably Polyethylene (PE) knotless, or can also be replaced with Polyamide. The cage dimensions are typically Length 5m x Width 3m x Depth 1.6m. The netting type is woven 210/14 – 210/16 (coarse 210, twisted by 14-16 fibers into netting strands). The mesh size varies depending on the size of the cultured fish and to prevent floating feed from escaping the cage, as indicated in the table below:

| Fish Sizes (cm) | Cage Mesh Sizes 2a (cm) |

|---|---|

| 5 - 10 | 1,0 |

| 10 - 15 | 1,5 |

| 15 - 20 | 2,0 |

| 20 - 30 | 2,5 - 3,0 |

| 30 - 50 | 3,0 - 5,0 |

| > 50 | 6,0 |

The frame section is made from fresh bamboo, free from cracks, relatively straight, uniform, and preferably with thorns. The bamboo poles are typically 4-5m long, connected with wire and anchored at the four corners of the cage. The assembly involves attaching the bottom, two longer sides, and two shorter sides independently, then joining them together to form a rectangular box shape, followed by installing the upper part of the cage. A single door is placed on the top of the cage for easy maintenance, monitoring of fish, and feeding.

The floating section can be assembled by connecting bamboo poles or using barrels, PVC containers, or waterproof fabric-covered styrofoam for support.

Aquaculture cages with bamboo frame nets are cost-effective, primarily using bamboo and twine for anchoring and connecting bamboo. Products from Siam Brothers Vietnam, with nationwide distribution, can be considered for purchase at "PRODUCT". Suitable for fishermen looking to engage in low-cost aquaculture, especially those living in wave-prone areas near the coast, ponds, lakes, rivers, etc.

Aquaculture cages with iron frame nets are similar to those with wooden and bamboo frames, with the main difference being that the frame is made of galvanized iron pipes, with zinc-coating to prevent rusting, with diameters of 34, 42, and 49. The suitable length is 6m.

Aquaculture cages with iron frame nets are less common than those with wooden or bamboo frames, and their cost is relatively moderate. However, they are more robust and durable. Suitable for fishermen looking to engage in low-cost aquaculture, especially those living in wave-prone areas near the coast, ponds, lakes, rivers, etc.

The cage section is made of nylon netting, preferably Polyethylene (PE) knotless, or can also be replaced with Polyamide. It is durable, resistant to oxidation, and can resist microbial adhesion, reinforced by bracing wires. The netting type is woven 210/14 – 210/16 (coarse 210, twisted by 14-16 fibers into netting strands). The mesh size varies depending on the size of the cultured fish and to prevent floating feed from escaping the cage, as indicated in the table below:

| Fish Sizes (cm) | Cage Mesh Sizes 2a (cm) |

|---|---|

| 5 - 10 | 1,0 |

| 10 - 15 | 1,5 |

| 15 - 20 | 2,0 |

| 20 - 30 | 2,5 - 3,0 |

| 30 - 50 | 3,0 - 5,0 |

| > 50 | 6,0 |

The frame section:

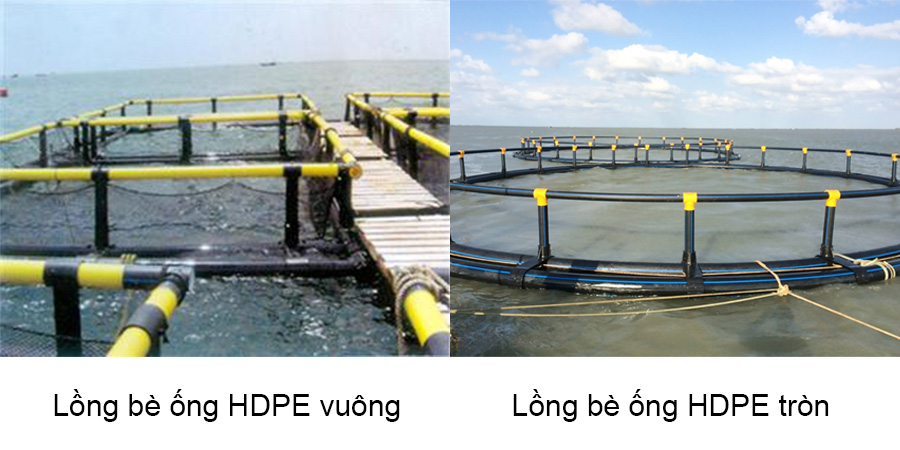

Square cages with frames made of HDPE plastic pipes, designed with multiple small square compartments interconnected. The system consists of 4-6 square compartments, each measuring 5 x 5 (m), linked together to form a system with walkable floors and connecting walkways.

Round cages with frames made of HDPE plastic pipes are also commonly used. The round cages have diameters of 12m, depth of 6m; diameters of 16m, depth of 8m; diameters of 20m, depth of 8m;…

The frame section is made of 100% HDPE plastic. HDPE pipes used for cage construction range from HDPE D90 pipes to HDPE D450 pipes. Each cage has a volume of approximately 1,200-2,400 m3, connected to anchor poles, with each pole weighing 3-4 tons according to Norwegian technology, ensuring the stability of the cage system. The anchor ropes are made of Polypropylene (PP) plastic, characterized by high tensile strength, resistance to oil, and anti-corrosion properties.

The HDPE pipe cages utilize Norwegian technology for anchor poles, making them robust and capable of withstanding up to a category 12 windstorm. The system allows farming in offshore areas with clean water, reducing the risk of pollution and diseases, controlling the quality of aquatic products, and avoiding conflicts with other interests such as maritime transportation and tourism in sheltered bays. The lifespan can reach up to 50 years, eliminating most drawbacks associated with traditional cages, such as susceptibility to corrosion, cumbersome design, environmental unfriendliness, and susceptibility to damage. Suitable for aquaculture with large-scale and long-term project investments.