Each type of tray has its own strengths, but choosing the wrong one could significantly reduce performance and efficiency. In this article, SIAM Brothers Vietnam will help you compare perforated and non-perforated plastic trays in terms of structure, practical applications, and key selection criteria. Let’s explore the differences and make a smarter, more cost-effective decision!

1. What Is a Perforated Plastic Tray? Key Features and Common Applications

A perforated plastic tray is designed with small holes or vents evenly distributed across its surface or side walls. These openings provide multiple benefits:

- Quick drainage and airflow, preventing moisture buildup

- Helps keep the tray dry and well-ventilated

- Reduces the risk of mold growth and product spoilage during use

- Depending on the intended purpose, perforated trays can be manufactured with varying hole densities, optimizing performance in specific sectors such as seedling propagation, fish handling, or agricultural drying.

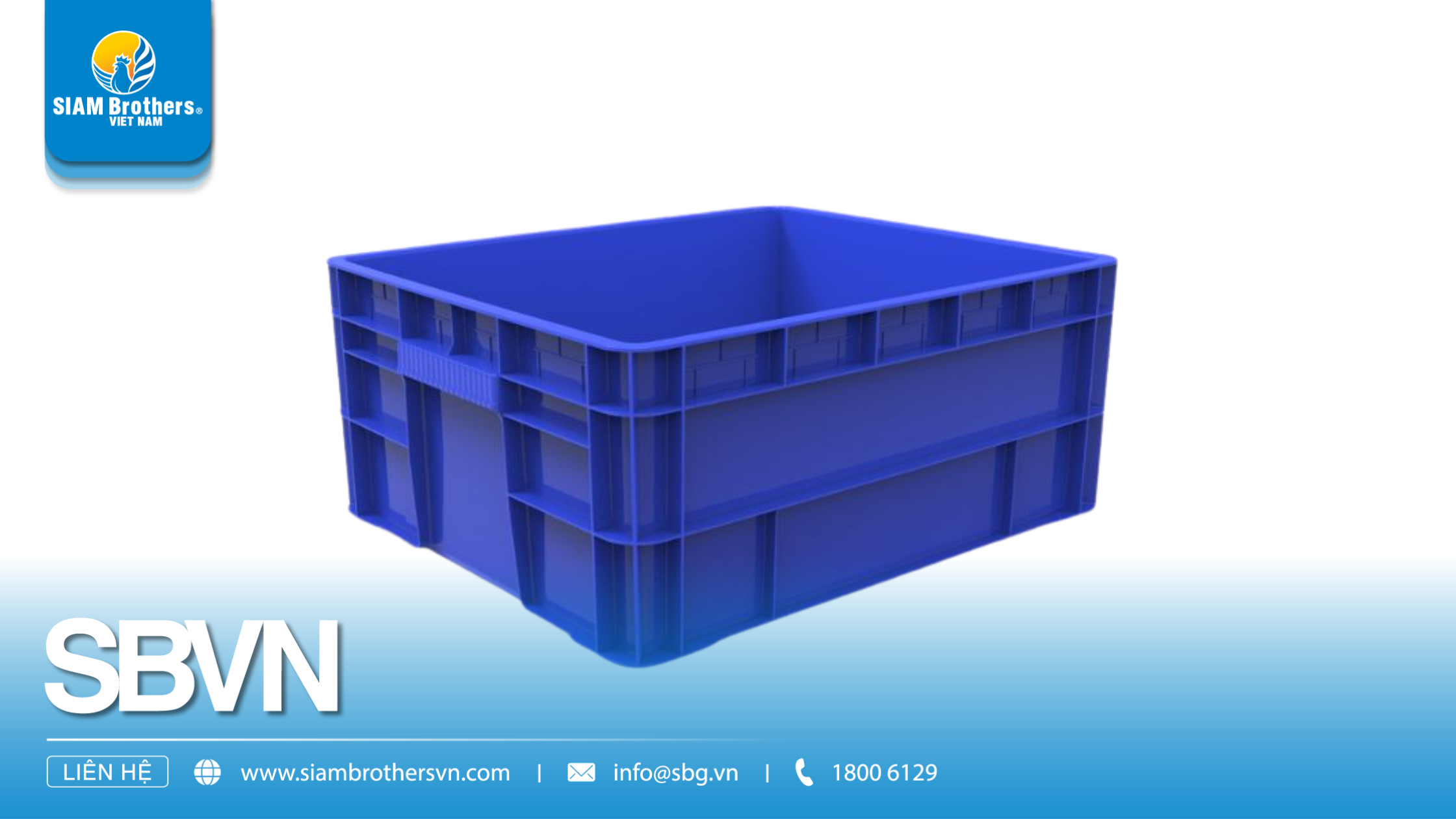

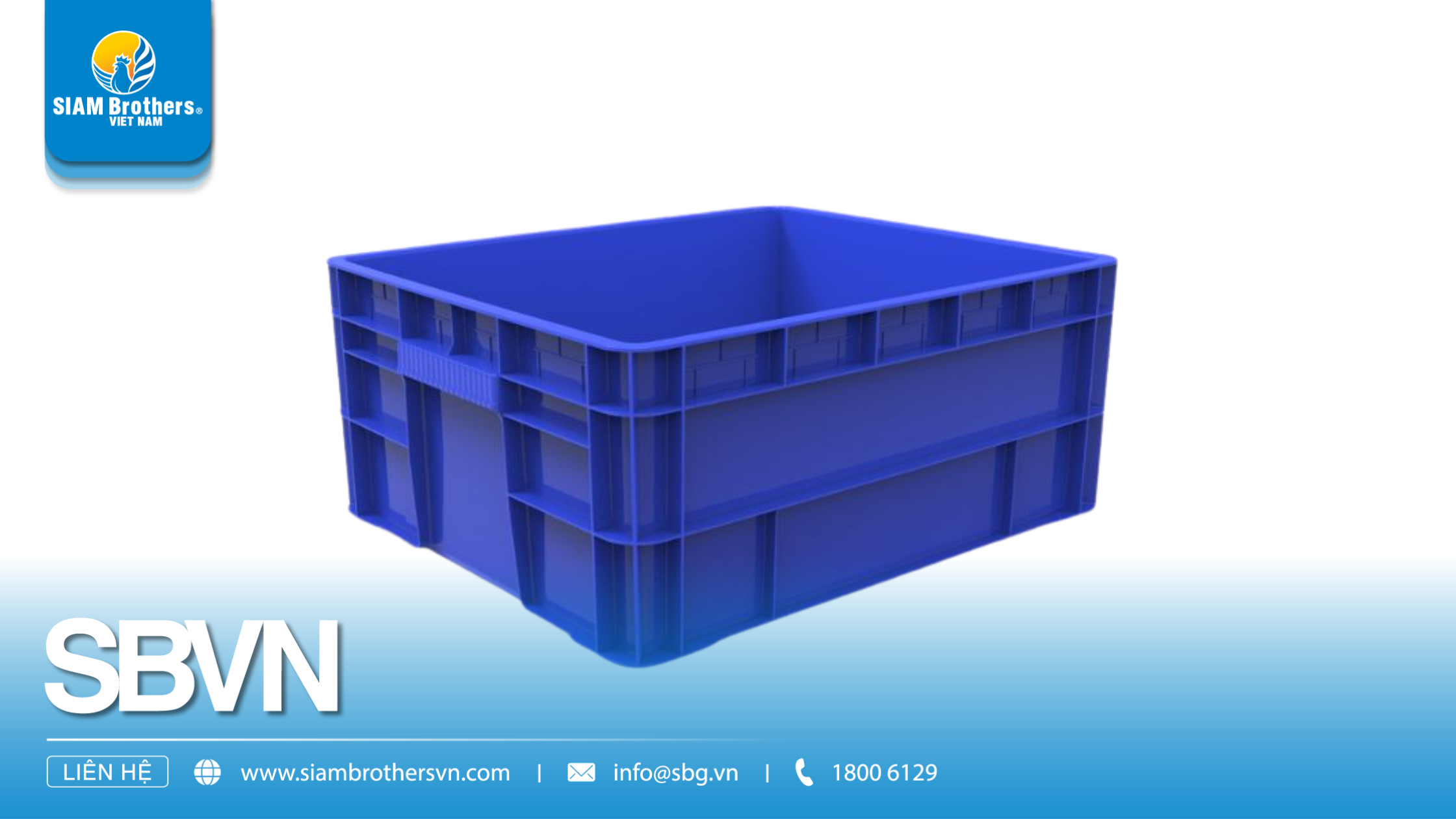

2. What Is a Non-Perforated Plastic Tray? When Should It Be Used?

A non-perforated plastic tray features a fully sealed surface and side walls with no drainage holes or vents. These trays are typically made from virgin PP or HDPE plastic, offering excellent durability and impact resistance.

Key Characteristics of Non-Perforated Plastic Trays:

- Seamless, smooth surface with no openings

- Capable of holding liquids or moist materials without leakage

- Easy to clean with no clogging from debris or water

- Strong, stable structure ideal for hygiene-sensitive environments

When Should You Use a Non-Perforated Plastic Tray?

Depending on your specific requirements, non-perforated trays can deliver optimal results in the following situations:

In Industrial and Logistics Applications:

- Storing items that don’t require ventilation, such as parts, tools, or mechanical components

- Transporting dry goods where leakage or spillage must be avoided

- Ideal for cold storage or automated production lines, with no airflow or dust accumulation through holes

In Agricultural Settings:

- Composting or moisture retention for soil and seeds

- Used to store agricultural materials like fertilizers, seeds, and pesticides

In the Food Industry:

- Holding fresh ingredients that need limited drainage

- Freezing products without ice buildup through perforations, maintaining hygienic standards

3. Detailed Comparison: Perforated Plastic Trays vs. Non-Perforated Plastic Trays

| Criteria |

Perforated Plastic Tray |

Non-Perforated Plastic Tray |

| Drainage Capability |

Equipped with drainage holes for quick water release and dry surface |

No holes; retains liquids and moisture within the tray |

| Ventilation |

Excellent ventilation; prevents mold growth on fresh produce or seedlings |

Limited airflow; suitable for high-moisture items or airtight storage |

| Agricultural Use |

Ideal for seedling trays, vegetable growing, drying crops |

Suitable for soil storage, fertilizer, seed handling |

| Aquaculture Use |

Great for storing fish, shrimp, or seafood – quick drainage maintains freshness |

Not ideal due to water retention, leading to spoilage |

| Industrial/Logistics Use |

Best for moisture-releasing or ventilated products |

Ideal for storing dry materials, mechanical parts, or discreet product transport |

| Ease of Cleaning |

Openings make cleaning easier but may require thorough rinsing to avoid buildup |

Sealed surface; easy to wipe clean with no residue trapped |

| Reusability |

Highly reusable in outdoor or greenhouse settings |

Durable and reusable, especially for warehouses and enclosed environments |

| Cost |

Generally more affordable due to simpler, common design |

Slightly higher cost due to thicker, fully sealed structure |

Summary: Which Tray Is Right for You?

Choose a Perforated Plastic Tray if you need:

- Efficient water drainage and ventilation

- A tray for agriculture, seed propagation, or storing fresh seafood

- Improved preservation and airflow in humid environments

Opt for a Non-Perforated Plastic Tray if you require:

- Storage for liquids, dry goods, or items needing moisture retention

- Easy-to-clean surfaces for cleanroom or closed system operations

- Leak-proof transport for dry or semi-liquid materials

4. FAQs – Frequently Asked Questions about Perforated and Non-Perforated Plastic Trays

4.1 Is a perforated plastic tray prone to damage when used outdoors?

Not at all. High-quality perforated plastic trays—like those from SIAM Brothers—are made from UV-resistant and heat-tolerant HDPE or PP. These materials ensure long-lasting durability outdoors without cracking, fading, or breaking.

4.2 Can I use a perforated plastic tray for storing fresh fish or shrimp?

Absolutely. Thanks to their excellent drainage design, perforated plastic trays are ideal for keeping seafood fresh by preventing water accumulation during harvesting, transport, or storage.

4.3 Can a non-perforated plastic tray hold fertilizer, soil, or liquids?

Yes. The fully sealed surface of a non-perforated plastic tray allows it to securely store fertilizers, seeds, moist soil, or liquids without any risk of leakage—making it ideal for warehouse use or hygiene-sensitive environments.

4.4 How can I choose the right type of tray for my needs?

- If you need ventilation and fast drainage, choose a perforated plastic tray.

- If you prefer moisture retention, leak-proof storage, or dry product protection, go for a non-perforated plastic tray.

- Also, consider factors such as indoor or outdoor use, product type, and intended reuse frequency.

4.5 Which type of tray is more durable?

Both trays are highly durable when made from virgin plastic or high-grade HDPE. However:

- Non-perforated trays typically have thicker walls, offering better sealing and load-bearing capacity for industrial use.

- Perforated trays are lightweight and flexible, easy to stack and carry, making them ideal for agricultural and outdoor operations.

4.6 Can I order custom-sized trays from SIAM Brothers Vietnam?

Yes. SIAM Brothers Vietnam offers custom manufacturing for both perforated and non-perforated plastic trays, including size, color, thickness, hole density, and more—tailored to your specific industry needs.

Choosing the correct tray type doesn’t just reduce costs—it also boosts performance across agriculture, aquaculture, and industrial workflows. If you need fast drainage and ventilation, especially for seedlings, seafood, or drying crops, then a perforated plastic tray is your go-to solution.

Conversely, if your priorities are moisture retention, leak prevention, or clean transport of dry goods, the non-perforated plastic tray offers clear advantages.

Still unsure which tray to choose? Our technical support team at SIAM Brothers Vietnam is ready to help you find the ideal solution for your specific use case.

Contact us today to receive a quick quote, explore custom tray options, and enjoy the best offers for bulk orders.