HDPE oyster farming floats have become the preferred solution for aquaculture farms thanks to their exceptional saltwater resistance, long lifespan of up to several decades, and optimized design for harsh marine environments. As oyster farming continues to expand from Vietnam’s central coastal regions to the Mekong Delta, investing in the right type of float is essential. The right float not only stabilizes suspended cages but also plays a decisive role in productivity and operating costs.

In this article, SIAM Brothers VN will guide you through the detailed structure, practical applications, and outstanding advantages of specialized HDPE floats for oyster farming—an innovation hailed as a “game-changer” in modern aquaculture.

1. What Is an HDPE Oyster Farming Float?

An HDPE oyster farming float is a buoyancy device made from High-Density Polyethylene (HDPE)—a durable, UV-resistant, and chemically inert plastic. It is specifically engineered for suspended oyster farming systems, helping secure ropes firmly on the water surface while withstanding pressure in rough sea conditions.

1.1 Key Features of HDPE Floats for Oyster Farming:

- Virgin HDPE material: Ensures superior durability, corrosion resistance, and high tensile strength—ideal for long-term use in saltwater and brackish environments.

- Seamless, one-piece design: Prevents leakage and maintains stable buoyancy over time.

- UV protection: Reduces brittleness and degradation from sun exposure.

- Lightweight and easy to install: Saves labor and speeds up farm setup.

1.2 Why Choose HDPE Floats Over Traditional Floats?

- Compared to foam, inflatable, or homemade alternatives, HDPE oyster farming floats offer a safer and more sustainable solution:

- Reduce risks of sinking due to leaks, rotting, or tearing.

- Lower maintenance and replacement costs per crop cycle.

2. Structure of HDPE Oyster Farming Floats

2.1 Main Components

Manufactured using modern blow-molding technology, the float typically includes:

- One-piece HDPE body: Provides resistance to saltwater, acids, and UV rays. Seamless design eliminates leakage.

- High-pressure air valve: For inflation and adjusting buoyancy; ensures airtight operation.

- Curved or concave base: Increases stability against waves and currents.

- Reinforced mooring points: For securely tying suspension ropes without slippage.

- Anti-slip surface: Enhances safety and ease of handling, even when wet.

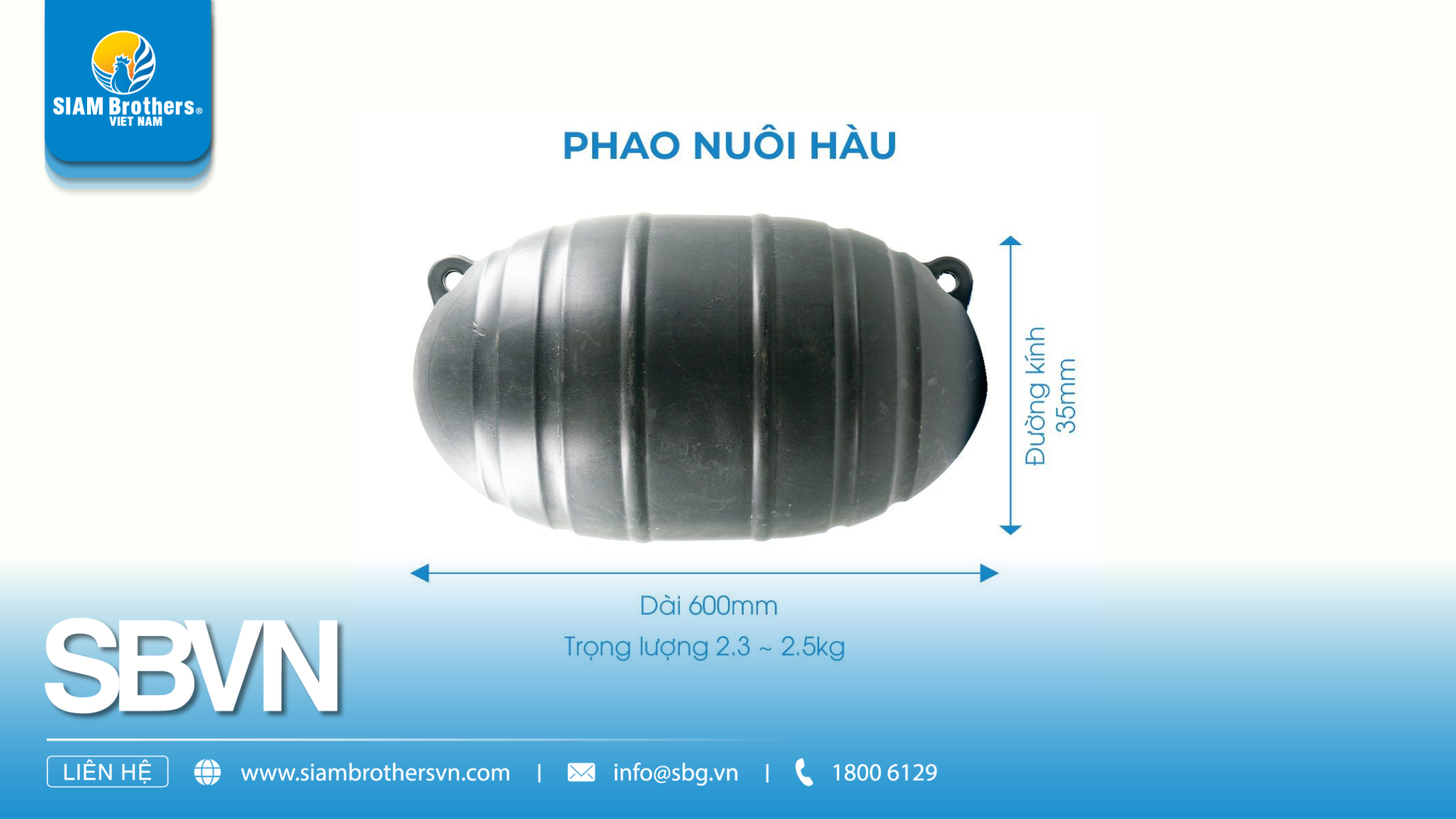

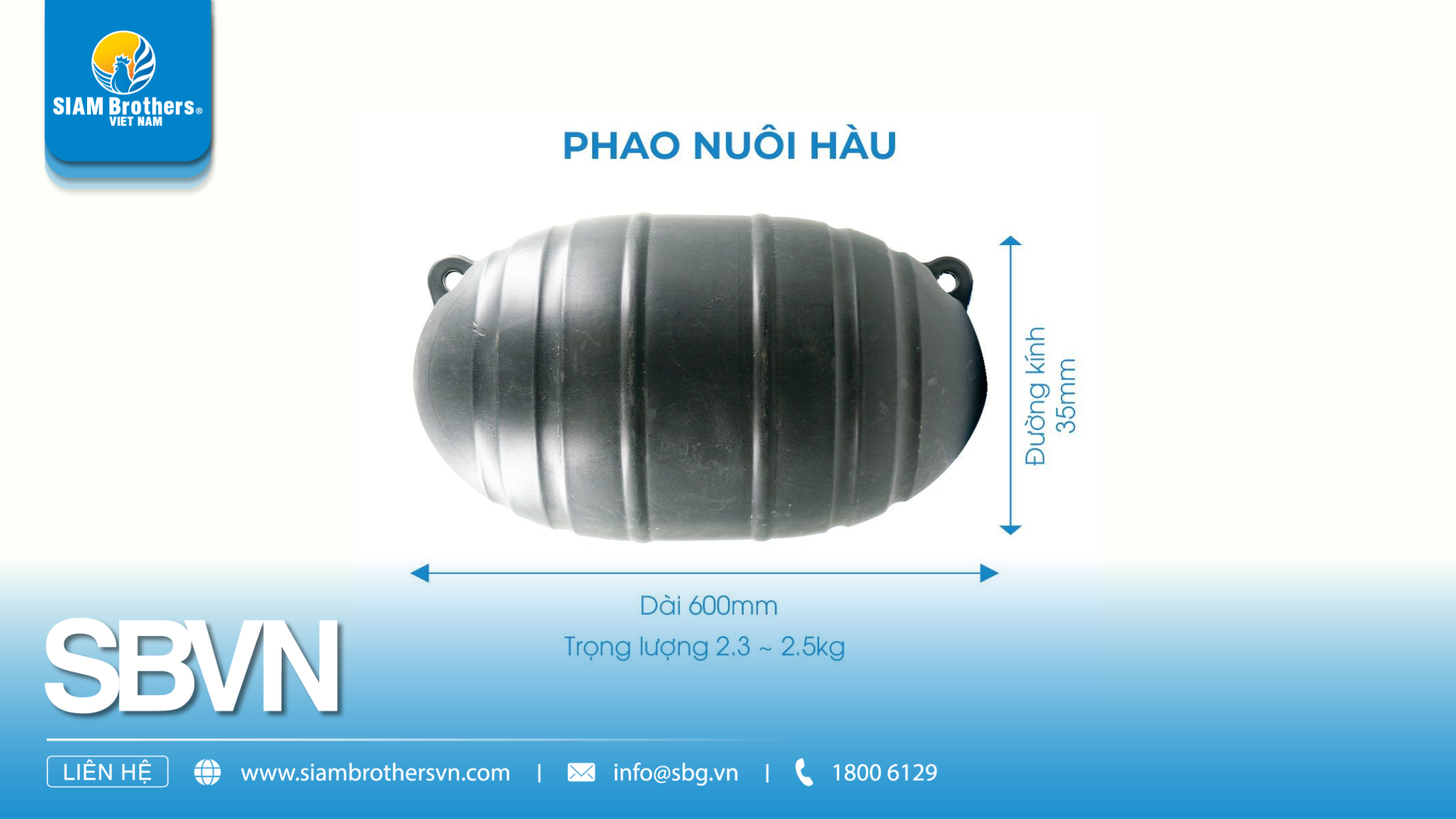

2.2 Key Technical Specifications

- Common sizes: 400–600 mm, depending on farm setup.

- Color options: Blue, orange, or black—enhancing visibility on water.

- Lightweight: Easy to transport with minimal labor.

- Average lifespan: 8–15 years, based on environmental conditions.

3. Highlighted Benefits of HDPE Floats in Oyster Farming

3.1 Optimized Buoyancy and System Stability

- Keeps suspended ropes stable on water, reducing tilting or flipping.

- Evenly distributes tension, minimizing stress on anchoring points.

3.2 Withstands Harsh Marine Conditions

- Engineered to function in strong currents, winds, and waves.

- Immune to sun, salt, and water pressure—key causes of damage in traditional floats.

3.3 Reduces Technical Failures During Farming

- High durability prevents bursting, air loss, or breakage—main reasons for cage collapse or seed loss.

- Minimizes repair and replacement costs.

3.4 Simplifies Installation and Inspection

- Lightweight build streamlines deployment and layout.

- Smart mooring points allow fast and safe adjustments.

3.5 Long-Term Economic Efficiency

- 8–15 year lifespan supports multiple farming cycles without frequent replacements.

- Reduces investment and maintenance costs, maximizing profitability.

4. Outstanding Advantages of HDPE Oyster Farming Floats Compared to Traditional Floats

4.1 Detailed Comparison Between HDPE Oyster Farming Floats and Traditional Floats

The table below highlights key differences to help you make an informed decision:

| Criteria |

Traditional Floats |

HDPE Oyster Farming Floats |

| Durability |

1–2 years |

8–15 years |

| Strength & Saltwater Resistance |

Low; easily cracked or rotted |

High; corrosion-resistant and impact-resistant |

| Stability in Rough Seas |

Easily overturned or drifted |

Firmly fixed and anti-capsize |

| Reusability |

Low; often needs replacing after each cycle |

Reusable across multiple farming cycles |

| Environmental Friendliness |

Often made from recycled materials |

Virgin HDPE – safe and eco-friendly |

| Long-term Cost Efficiency |

Lower upfront, higher in the long run |

Higher upfront but cost-saving in long-term use |

4.2 Summary of Key Advantages of HDPE Oyster Farming Floats

- Extended Lifespan: Unlike foam or rubber floats, HDPE floats resist aging and wear, helping reduce replacement costs.

- Reliable in Harsh Conditions: Ideal for coastal areas with strong waves, dense saltwater, or frequent storms.

- Optimized for Oyster Farming: Maintains stable buoyancy, protects suspension rope systems, and minimizes stock loss.

- Easy to Maintain and Adjust: Lightweight and easy to install; convenient for inspection or repositioning.

- Cost-Effective Investment: While initial costs may be higher, long-term usage results in significant savings over traditional floats.

5. FAQs – Frequently Asked Questions About HDPE Oyster Farming Floats

5.1 What is the average lifespan of an HDPE oyster farming float?

- On average, HDPE oyster farming floats last 5–10 years, depending on environmental conditions and usage.

- Thanks to their corrosion resistance and immunity to UV and saltwater damage, these floats maintain excellent performance over time.

5.2 Are HDPE oyster farming floats environmentally friendly?

- Yes. HDPE is a recyclable material and does not release harmful substances during use.

- Using HDPE oyster farming floats helps reduce plastic waste from degraded or broken floats, a major source of marine pollution.

5.3 Are HDPE floats more expensive than traditional floats?

- While the initial cost of HDPE floats may be slightly higher, they offer much greater long-term savings due to their durability and low maintenance requirements.

- They also reduce the need for frequent replacements, contributing to a more stable and sustainable farming model.

5.4 Can HDPE oyster farming floats be used for other aquatic species?

Absolutely. In addition to oyster farming, HDPE floats are suitable for clam farming, mussel cultivation, and even seaweed aquaculture, depending on the design of your raft or cage system.

5.5 Where can I buy high-quality HDPE oyster farming floats?

- SIAM Brothers Vietnam is proud to be a leading manufacturer of HDPE oyster farming floats, trusted by aquaculture farms across the country.

- Our products meet international quality standards and undergo strict quality control before delivery.

HDPE oyster farming floats are more than just a replacement for traditional buoys—they are a sustainable, high-performance solution for today’s aquaculture industry.

With robust structure, long service life, strong load resistance, and eco-friendliness, HDPE floats have become the preferred choice for oyster farmers in Vietnam and Southeast Asia.

If you’re looking for a high-quality, cost-effective, and easy-to-install HDPE oyster farming float that supports long-term aquaculture success—SIAM Brothers Vietnam is your trusted partner.

Contact us today for tailored advice and the best quote for your aquaculture model!