Floating buoys are an essential component in aquaculture cage systems, directly determining the safety and durability of floating structures. However, not everyone fully understands how to properly install and maintain floating buoys to achieve the highest performance.

This guide provides detailed, step-by-step instructions — from preparation and assembly to inspection and regular maintenance — helping ensure stable buoy performance, prevent leakage, and extend the product’s lifespan. Discover professional tips from SIAM Brothers Vietnam experts to maintain a safe and cost-efficient buoy system.

1. Understanding the Structure and Working Principle of Floating Buoys

1.1. Basic Structure of Floating Buoys

Before installation, understanding the structure of a floating buoy allows operators to perform maintenance and inspections more effectively. A high-quality buoy typically consists of the following main components:

- Buoy Body: Made from premium HDPE material, resistant to UV rays, seawater corrosion, and capable of maintaining buoyancy stability over long periods.

- Buoy Cap: Designed with a tight seal to prevent water and air intrusion, ensuring complete internal protection.

- Air Valve or Pressure Relief Vent: Helps maintain internal pressure, preventing swelling or deformation caused by temperature changes.

- Anchoring Ears or Connectors: Used to attach buoys to cage frames, ensuring the entire system remains stable even in rough water conditions.

1.2. Working Principle of HDPE Floating Buoys

Understanding how HDPE floating buoys function helps maximize their efficiency and lifespan:

- Based on Archimedes’ Principle, floating buoys generate an upward force strong enough to keep the cage frame and stock stable on the water surface.

- When water levels rise or waves increase, the buoy body automatically adjusts its buoyancy to maintain balance, preventing tilting or submersion.

- Thanks to their sealed construction and lightweight material, HDPE buoys evenly distribute force across the entire cage frame, reducing pressure on joints and structural supports.

1.3. Why Understanding Buoy Structure Matters

For fish or aquaculture cage operators, understanding the design and working principle of floating buoys not only ensures proper installation but also:

- Makes it easier to detect damage, leaks, or deformations.

- Enables proactive maintenance and timely component replacement.

- Improves operational efficiency and reduces long-term repair costs.

Expert Tip: When purchasing floating buoys, prioritize HDPE products certified for UV resistance and chemical durability — like those manufactured by SIAM Brothers Vietnam, designed specifically for Vietnamese marine conditions to ensure long-lasting performance and safety in aquaculture.

2. Preparation Before Installing Floating Buoys

2.1. Assessing Location and Environmental Conditions

Before installation, evaluate site conditions to select the most suitable type of floating buoy:

- Water Depth and Salinity: These factors directly affect buoyancy and product lifespan.

- Current Speed and Wind Direction: Determine the number of buoys required to maintain cage balance.

- Seabed or Lakebed Terrain: Avoid areas with rocks or sharp objects that could damage buoys.

- Wave Intensity: In rougher waters, choose HDPE floating buoys with thicker walls and secure locking systems.

To ensure a smooth installation process, prepare all necessary tools and accessories in advance:

- Mooring Ropes and Lines: Used to fix buoys and cage frames, ensuring stability even in strong waves.

- Connectors, Bolts, and Stainless Steel Clamps: Combine buoy units into a unified system.

- Water Level Gauges, Measuring Tools, and Marker Buoys: Help calibrate accurate depth and spacing between buoy modules.

- Personal Protective Equipment (PPE): Include life vests, gloves, and safety glasses to ensure safe installation on the water surface.

2.3. Inspecting Buoy Condition Before Use

Never skip a thorough inspection before installation to prevent technical issues during operation:

- Check the Buoy Surface: Ensure no cracks, bulges, or deformations.

- Inspect Caps and Seals: Confirm airtight and watertight conditions.

- Test Buoyancy: Submerge the buoy to ensure proper stability and balance.

- Verify Quantity: Match the number of buoys with the cage frame design to guarantee load capacity and structural integrity.

2.4. Pro Tips from SIAM Brothers Vietnam Experts

To achieve the best installation results, the SIAM Brothers Vietnam technical team recommends:

- Use virgin HDPE floating buoys certified for UV resistance and seawater corrosion protection.

- Combine buoys with compatible mooring ropes and accessories from the same brand to ensure system consistency and minimize the risk of failure.

3. Floating Buoy Installation Process — Step-by-Step Guide

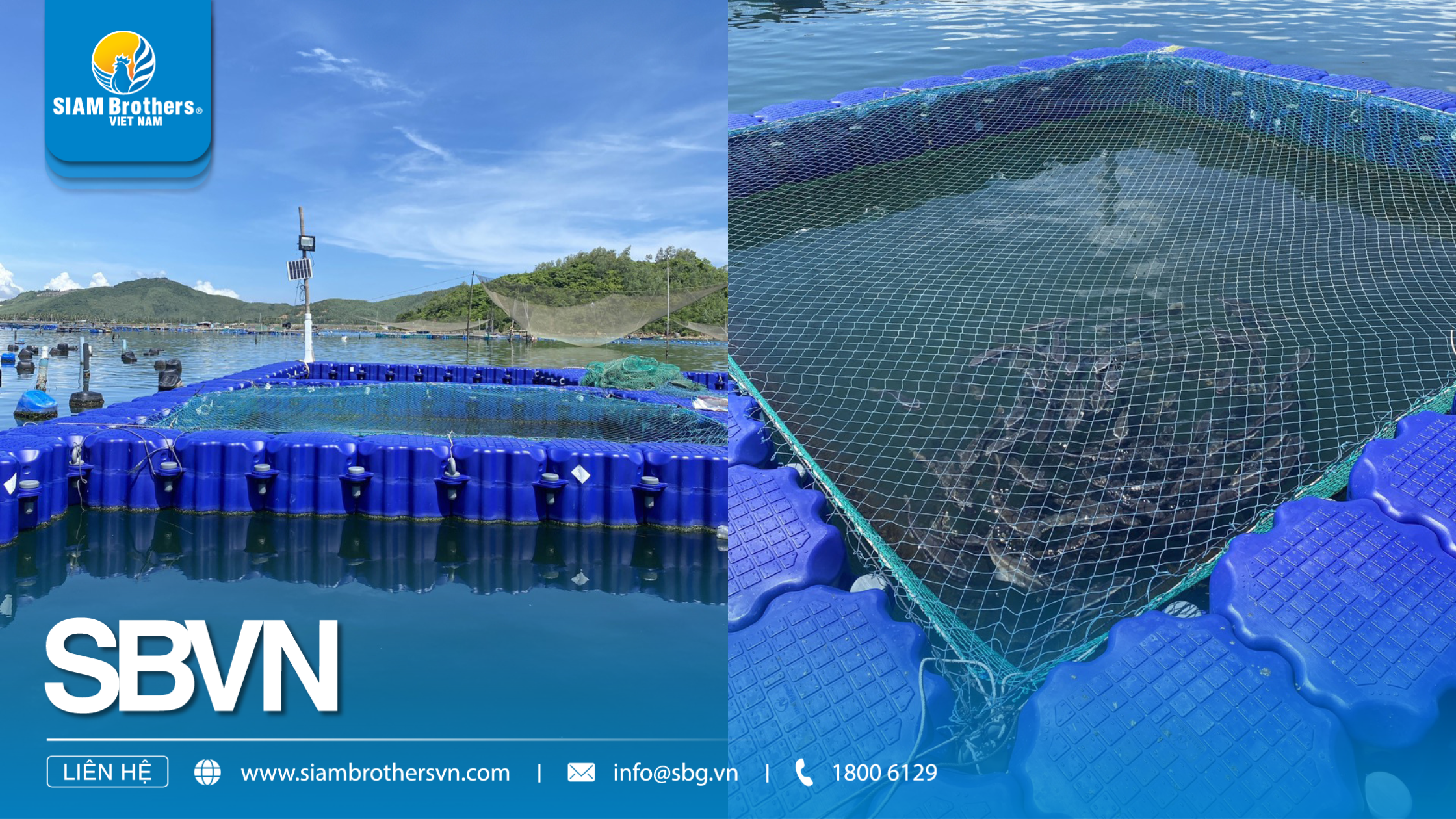

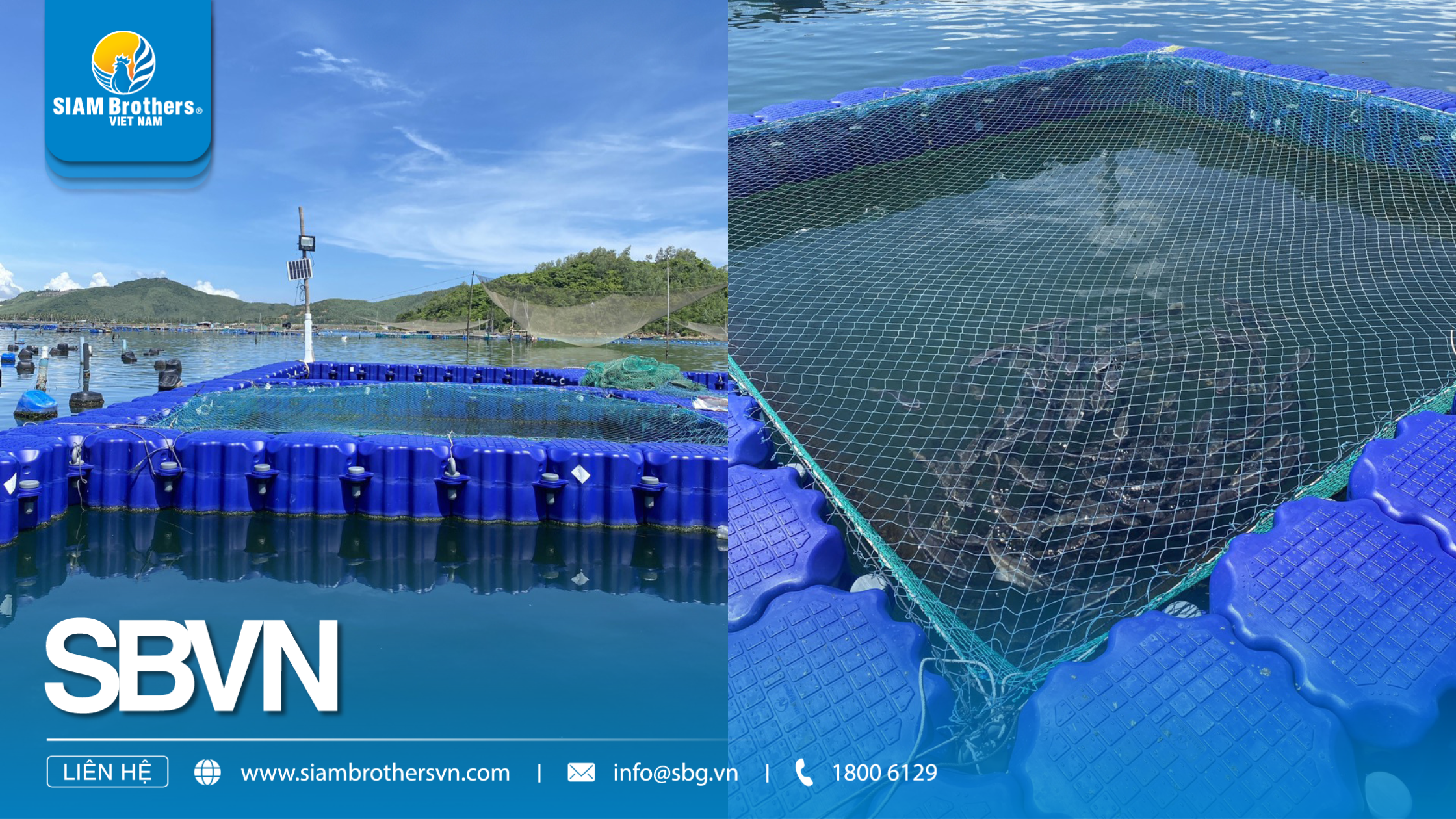

3.1. Step 1: Identify the Location and Plan the Buoy System

Before installing the floating buoys, it’s essential to clearly define the installation area and design a balanced layout to ensure even load distribution across the entire system:

- Mark the installation area using positioning buoys or temporary anchor ropes.

- Determine the distance between floating buoy clusters according to the technical design of the aquaculture raft.

- Consider wind direction and water flow to position the buoys strategically, minimizing water pressure on the raft frame.

- Ensure uniform buoyancy among all buoy clusters to prevent tilting or instability during operation.

Tip: Perform installation in calm water and low-wind conditions to avoid misalignment of buoy clusters.

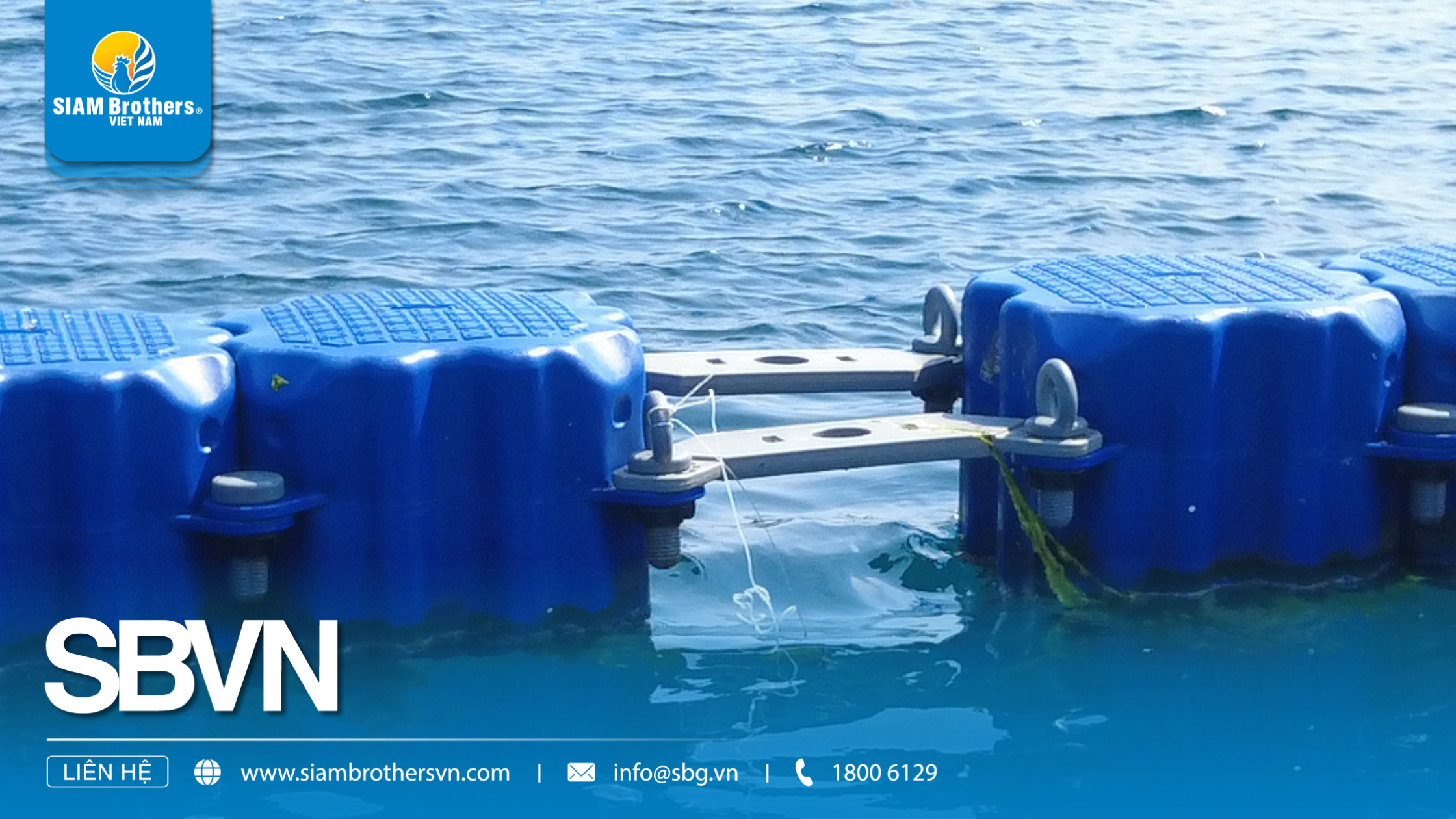

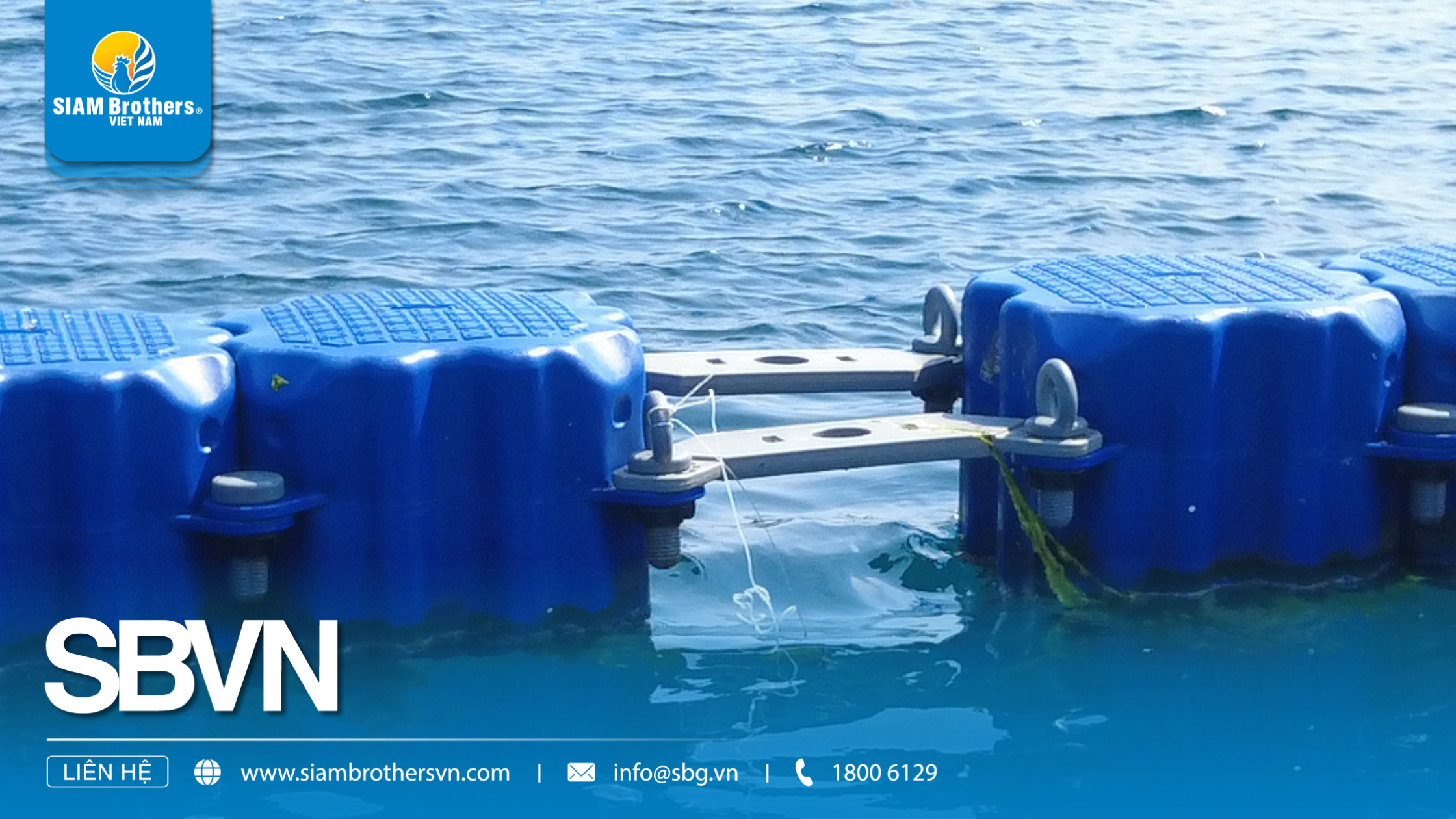

3.2. Step 2: Connect the Floating Buoy Clusters

Once the positions are determined, proceed to assemble the floating buoys into unified clusters:

- Use HDPE joints or connecting pipes to interlink the buoys.

- Tighten bolts, stainless-steel bands, or durable ropes to ensure secure connections.

- Inspect all joints to avoid gaps, misalignments, or leaks.

- Assemble according to the pre-designed layout to control the quantity and placement of each buoy.

Expert Tip: Keep the buoys aligned and leveled throughout the assembly to maintain balance and uniform floating performance.

3.3. Step 3: Secure the Floating Buoy System to the Raft Frame

When the buoy clusters are fully connected, the next step is to secure them to the raft structure:

- Use HDPE ropes or anchor lines to fasten the buoys to the frame.

- Tie firmly at four corners and key points to prevent movement under strong waves or winds.

- Adjust rope tension to maintain the designed buoyancy — preventing submersion or off-center floating.

- Test overall stability by gently moving the raft and observing its response.

3.4. Step 4: Inspection, Testing, and Adjustment

Before the official operation, a technical inspection of the floating buoy system is mandatory to ensure safety and stability:

- Test load capacity by applying a weight equivalent to the actual conditions (cages, equipment, or operators).

- Observe for any tilting, water overflow, or uneven buoyancy.

- Adjust buoy positions or anchor ropes if any discrepancies are detected.

- Record real technical data as a reference for future maintenance.

3.5. Step 5: Completion and Handover

Once the system passes inspection, finalize the installation and prepare for handover:

- Label each buoy cluster with a code or color mark for easier identification during maintenance.

- Keep a detailed layout plan and technical specifications for scheduled servicing.

- Recheck all fasteners, joints, and ropes to ensure maximum durability and safety.

Expert Tips from SIAM Brothers Vietnam

- Choose high-quality HDPE floating buoys made from 100% virgin material with UV resistance, saltwater tolerance, and anti-cracking durability.

- Use genuine connectors, anchors, and accessories to ensure a synchronized and long-lasting system.

- Inspect the floating buoy system every 6 months, especially after storms or strong tidal changes.

4. Technical Tips & Safety Precautions for Floating Buoy Installation

4.1. Technical Tips for Maximum Floating Buoy Efficiency

- Choose the right size and load capacity: Each buoy type supports different weights — select based on the total load of cages, equipment, and operators.

- Use premium HDPE buoys: Prioritize UV-resistant, saltwater-tolerant, and impact-resistant HDPE buoys for long-term performance in harsh environments.

- Connect buoys properly: Use stainless-steel bands, durable joints, and high-strength ropes. Avoid galvanized wires that may rust and damage the buoys over time.

- Maintain balance during installation: After assembling each buoy cluster, test buoyancy using a simulated load. Adjust rope tension or buoy positions if tilting occurs.

4.2. Safety Guidelines During Floating Buoy Installation

- Wear full protective gear: Workers must wear life jackets, non-slip gloves, and helmets when working on water surfaces.

- Avoid installation in bad weather: Do not proceed during heavy rain, strong winds, or high waves, as this affects accuracy and increases risks.

- Ensure electrical and mechanical safety: Use insulated, anti-shock power sources for welding or electrical equipment near water.

- Maintain balance during movement: When installing multiple buoy clusters, limit the number of people on a single section to prevent instability.

- Perform a final safety check: Once installation is complete, conduct a light load test and inspect all joints and buoy balance before operation.

4.3. Practical Experience from SIAM Brothers Vietnam Experts

- Always record technical parameters and buoy layouts for easy maintenance tracking.

- When installing HDPE floating buoys in saltwater, apply a light anti-corrosion layer to metal joints.

- Inspect buoyancy and sealing every 3–6 months, especially after extreme weather.

- When replacing damaged buoys, replace them in pairs or symmetrical positions to maintain overall balance.

5. FAQs – Common Questions About Floating Buoy Installation

5.1 What should be considered to ensure safety during floating buoy installation?

To ensure long-term stability and safety of your floating buoy system, you should:

- Check the water surface condition: Choose an area with stable depth and current.

- Distribute buoys evenly: Balance the load to prevent cage tilting or instability.

- Use certified accessories: Anchors, connectors, and cage frames should be made from anti-rust materials.

- Perform regular inspections: After installation, check the buoy’s sealing and buoyancy every 3–6 months.

5.2 How often should floating buoys be maintained?

Regular maintenance helps extend the lifespan of floating buoys and minimize replacement costs:

- Every 6 months: Inspect the outer surface for cracks, swelling, or scratches.

- Annually: Clean moss, mud, or algae to maintain buoyancy and reduce water friction.

- After extreme weather: Increase inspection frequency, especially after storms or heavy rains.

Pro tip: Keep a maintenance logbook to track performance and assess the condition of each buoy over time.

5.3 Can old floating buoys be reused?

Yes, floating buoys can be reused, but only after careful inspection and testing:

- Check for water leakage: The buoy must be free from cracks or holes.

- Test buoyancy: If the buoyancy is reduced by more than 20% compared to the original, replacement is recommended.

- Clean thoroughly before reuse: Remove moss, oil, or marine organisms attached to the buoy.

Reusing standard-quality floating buoys helps reduce operational costs while maintaining aquaculture efficiency.

5.4 How to choose the right floating buoy for your aquaculture system?

When selecting floating buoys, consider the following three key factors:

- Material: Choose buoys made from virgin HDPE for high durability and excellent UV resistance.

- Size & load capacity: Select buoys that can support the total weight of cages, equipment, and operators.

- Reliable supplier: Choose a manufacturer with quality certification and clear inspection processes.

Suggestion: The HDPE floating buoys from SIAM Brothers Vietnam are designed specifically for both saltwater and brackish environments — suitable for small-scale and industrial aquaculture operations.

5.5 What is the average lifespan of floating buoys when used properly?

High-quality floating buoys can last from 10 to 15 years, depending on usage conditions and maintenance practices:

- In clean, low-corrosion water: Lifespan can reach up to 15 years.

- In saltwater or rough conditions: Conduct more frequent inspections to maintain performance.

Note: The plastic quality and sealed welding technique are key factors that determine the buoy’s durability.

5.6 Where can I buy high-quality floating buoys with reliable after-sales service?

It’s best to choose a direct manufacturer such as SIAM Brothers Vietnam, where you’ll get:

- International-standard HDPE floating buoys.

- On-site installation and maintenance support from experienced technicians.

- Comprehensive warranty and expert consultation for optimized aquaculture solutions.

Understanding how to properly install, maintain, and select floating buoys helps reduce costs, increase aquaculture productivity, and ensure long-term system safety.

If you need technical consultation or customized floating buoy solutions, contact SIAM Brothers Vietnam — a leading manufacturer and distributor of premium HDPE floating buoys in Vietnam.

Source: SIAM Brothers Vietnam

Contact us:

► Address: 5th floor, VRG Building, 177 Hai Ba Trung Street., Xuan Hoa Ward, Ho Chi Minh City, Vietnam

► Hotline: 1800 6129

► Tel: (+84) 28 38 912 889

► Email: info@sbg.vn

► Follow us for more details at: Facebook - Zalo OA - Tiktok - Youtube - LinkedIn

Download SBVN ID app here:

► CHPlay

► Appstore