Choosing the right rope for saltwater environments doesn't just impact the efficiency of your work—it directly affects safety and the lifespan of equipment used in industries such as maritime, fishing, offshore construction, and logistics. Saltwater is a harsh environment that can cause corrosion, rot, reduced tensile strength, and instability in many materials, including rope. Each type of rope—whether it's nylon, polyester, polypropylene (PP), stainless steel wire, or high-performance rope like HMPE—has its technical properties suitable for different demands, such as load capacity, stretch, UV resistance, and water resistance. Understanding these differences is key to selecting the right rope for your specific application. In this article, let’s explore with SIAM Brothers Vietnam: what is the best rope for saltwater use?

Source: Internet

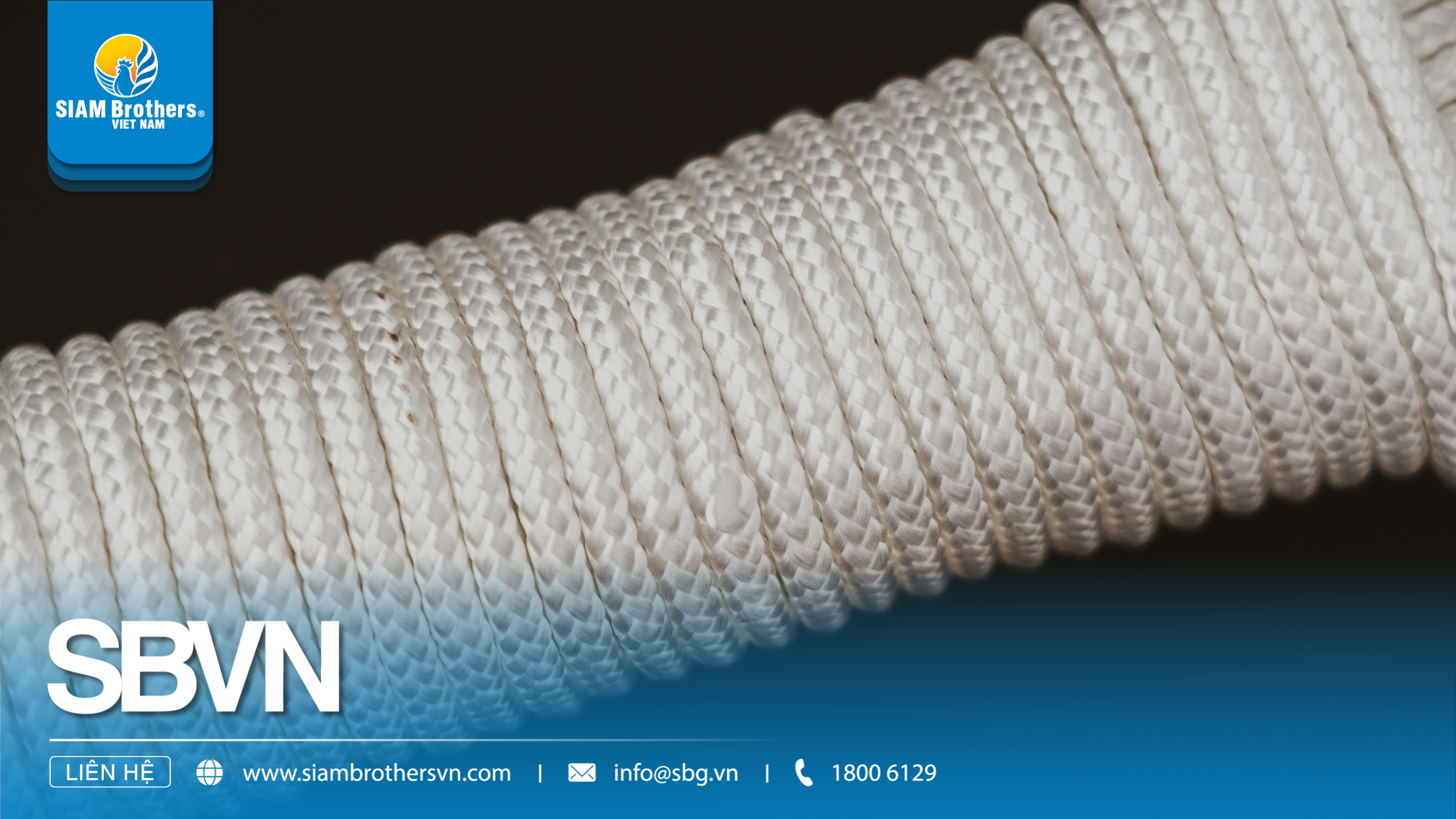

Polypropylene rope is a popular choice in saltwater environments due to its lightweight nature and ability to float on water. However, this type of rope has a lower tensile strength than nylon and polyester and offers poor UV resistance, making it susceptible to degradation when exposed to prolonged sunlight. Therefore, PP rope is often used in temporary applications like lifelines or marker lines.

PP rope is lightweight and floats, making it suitable for lifelines and marker buoys applications. It is also water-resistant and resistant to mold. Its production cost is low, making it a budget-friendly option.

Its tensile strength is lower than nylon or polyester. It has poor UV resistance and can degrade over time with prolonged sun exposure.

Lifelines, marker buoys, temporary tie-downs.

Source: Internet

Nylon rope stands out for its high tensile strength and excellent elasticity, which makes it great at absorbing shock. This makes it an ideal choice for mooring and towing applications. However, nylon tends to absorb water, which can reduce its strength when wet. Its UV resistance is moderate, so additional UV treatment is recommended for prolonged outdoor use.

Nylon rope offers high strength and excellent shock absorption, making it suitable for mooring and towing. It has good resistance to abrasion and many chemicals.

It absorbs water, and its tensile strength decreases when wet. UV resistance is only moderate and should be enhanced with additional treatments for outdoor use.

Mooring lines, towing ropes, rescue ropes.

Source: Internet

Polyester rope is highly regarded in saltwater environments due to its excellent resistance to both UV rays and water. It is not affected by wet conditions and maintains its shape under load thanks to its low stretch. These properties make it ideal for fixed mooring lines, cargo tie-downs, and safety nets.

Excellent resistance to UV and water, unaffected by wet environments. Low stretch, stable under tension. Strong resistance to abrasion and chemicals.

Low elasticity—does not absorb shock as well as nylon.

Fixed mooring lines, cargo tie-downs, safety nets.

Source: SIAM Brothers Vietnam

HMPE rope is made from ultra-high molecular weight polyethylene (UHMWPE) fibers, one of the strongest synthetic materials available. It offers an exceptional strength-to-weight ratio, stronger than steel on a per-weight basis.

HMPE rope performs excellently in resisting UV, chemicals, and abrasion. It does not absorb water and floats. However, its high cost makes it suitable mainly for specialized applications such as large-vessel mooring and industrial towing.

Extremely high tensile strength, lighter than steel yet stronger. Exceptional UV, chemical, and abrasion resistance. Water-repellent and buoyant.

More expensive than other rope materials.

Mooring lines for large vessels, industrial towing, and professional rescue operations.

Source: Internet

Stainless steel wire rope has very high tensile strength and can handle heavy loads. It is also highly corrosion-resistant in saltwater environments. However, it is heavy, inflexible, and difficult to handle. Its high cost also limits its use to specific fixed-load applications.

Very high strength and load-bearing capacity. Excellent corrosion resistance in marine environments.

Heavy, difficult to handle, and not flexible. Expensive.

Fixed mooring, rigging, heavy-load bearing lines.

Comparison Table of Rope Types

|

Criteria |

PP Rope |

Nylon Rope |

Polyester Rope |

HMPE Rope |

Stainless Steel Wire Rope |

|

Tensile Strength |

Low |

High |

High |

Very High |

Very High |

|

Stretchability |

Medium |

High |

Low |

Very Low |

Very Low |

|

Water Resistance |

Good |

Medium |

Excellent |

Excellent |

Excellent |

|

UV Resistance |

Poor |

Medium |

Excellent |

Excellent |

Excellent |

|

Weight |

Very Light |

Medium |

Medium |

Very Light |

Very Heavy |

|

Cost |

Low |

Medium |

Medium |

High |

Very High |

|

Primary Application |

Lifelines |

Mooring, Towing |

Cargo Securing |

Industrial Use |

Heavy Load Applications |

Choosing the right type of rope for saltwater environments depends on your specific needs:

If you need a lightweight rope that floats on water and comes at a low cost, PP rope is a suitable choice.

If you require a rope with good elasticity and effective shock absorption, nylon rope is an ideal option.

Polyester rope is the optimal choice if you're looking for a durable rope with excellent resistance to UV rays and water.

If you need a rope with extremely high tensile strength, lightweight properties, and excellent abrasion resistance, HMPE rope is the top choice.

Stainless steel wire rope is the most appropriate solution if your application demands a rope that can handle heavy loads and resist corrosion in saltwater environments.

Read more: The Future of the Rope Manufacturing Industry

Source: SIAM Brothers Vietnam

Contact us:

Address: 5th floor, VRG Building, 177 Hai Ba Trung Street., Vo Thi Sau Ward, District. 12, Ho Chi Minh City, Vietnam

Tel: (+84) 28 38 912 889

Hotline: 1800 6129

Facebook: www.facebook.com/siambrothersvn

Email: info@sbg.vn

YouTube: youtube.com/@siambrothersvietnam1728

OA Zalo: zalo.me/1402339229697925373

App SBVN ID:

CHPlay: https://bit.ly/SBVNID-Android

Appstore: https://bit.ly/SBVNID-iOS