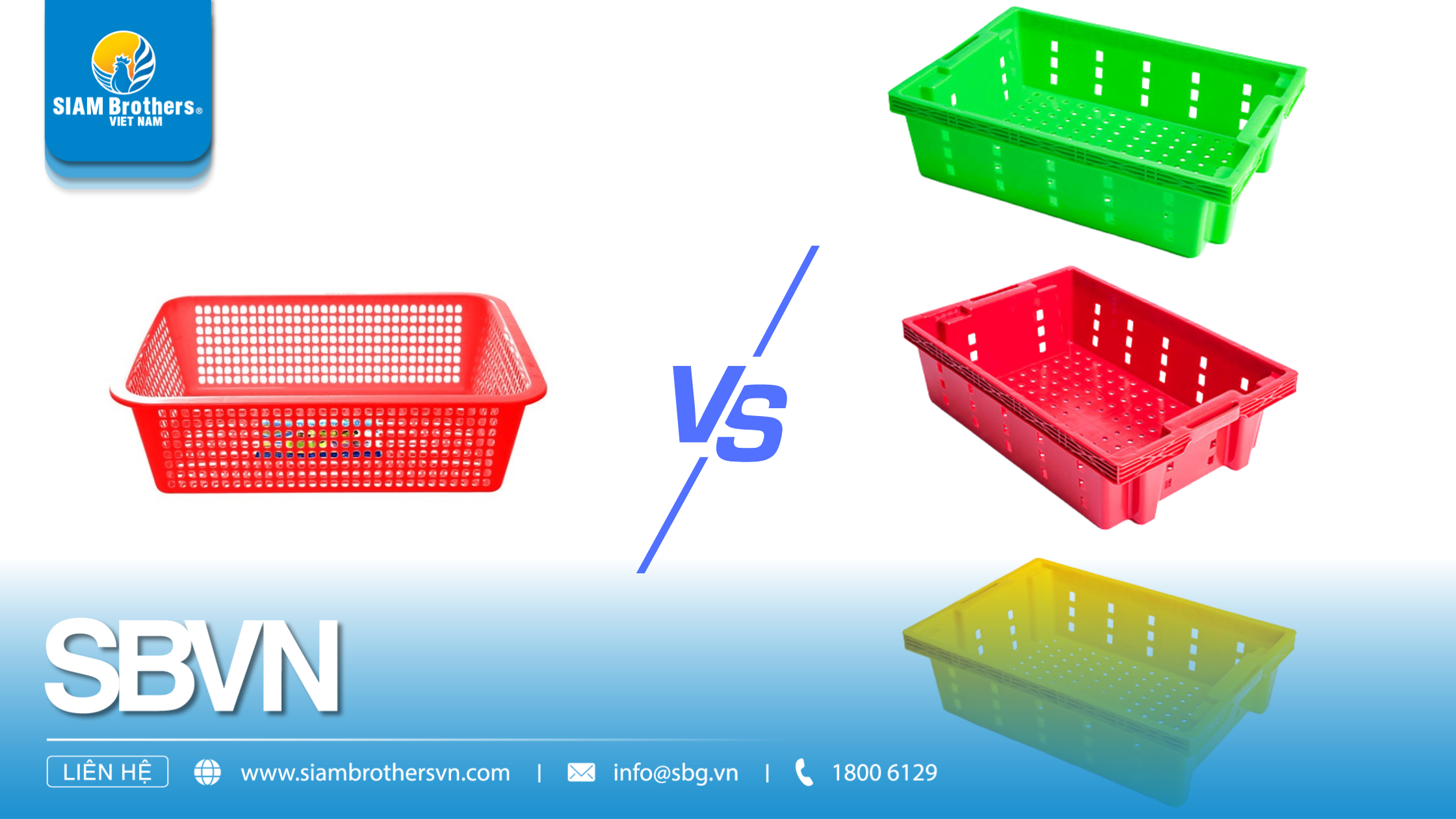

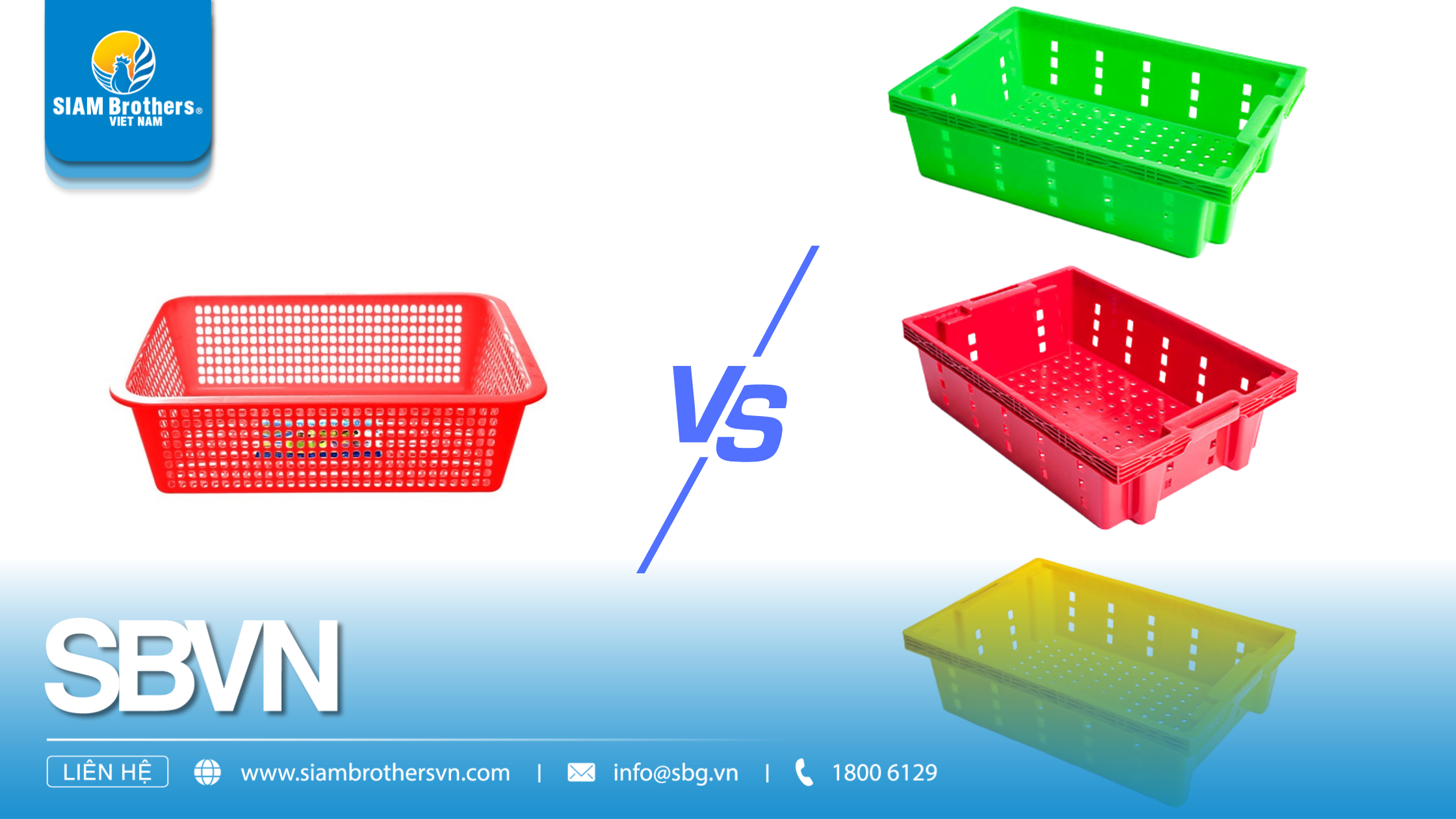

Not all plastic trays are created equal. At first glance, they may look similar—but in reality, there are significant differences between specialized plastic trays and regular ones in terms of material, durability, load capacity, and environmental adaptability. The detailed comparison table below will help you discover the smarter choice—especially if you're working in agriculture, aquaculture, or logistics. Let SIAM Brothers Vietnam guide you in making the right investment and maximizing usage efficiency from the start.

1. What Are Specialized Plastic Trays and Regular Plastic Trays?

1.1 What Are Specialized Plastic Trays?

Specialized plastic trays are made from virgin plastic materials such as HDPE or PP, manufactured according to strict technical standards. These trays are designed to withstand demanding working environments like agriculture, aquaculture, food processing, warehousing, and logistics.

Key features of specialized plastic trays:

- High load capacity: Reinforced structure, resistant to heavy loads, and deformation when stacked.

- Superior durability: UV-resistant, corrosion-resistant in salty or chemical-rich environments, and tolerant to extreme temperatures.

- Operational efficiency: Stackable design, easy to clean and transport, space-saving in storage.

- Variety of sizes and colors: Adaptable to specific industries and practical applications.

- Meets hygiene standards: Safe for use in food supply chains and seafood processing facilities.

1.2 What Are Regular Plastic Trays?

Regular plastic trays are mass-market products, typically made from recycled or mixed plastic. These trays serve simple daily purposes in home and office settings.

Basic characteristics of regular plastic trays:

- Low cost: Suitable for short-term use with minimal technical requirements.

- Limited durability: Prone to cracking or warping under heavy pressure or impact.

- Not suitable for harsh environments: Quickly degrades with prolonged exposure to sunlight, moisture, or fluctuating temperatures.

- Low load capacity and short lifespan: Best used for lightweight items in residential or office spaces.

2. Why It’s Important to Distinguish Between Specialized and Regular Plastic Trays

2.1 Different trays serve different purposes

-

Specialized plastic trays are engineered for environments requiring high resistance to weight, heat, chemicals, or direct contact with food and liquids.

-

In contrast, regular trays are designed for light-duty tasks and indoor use, and cannot handle industrial stress or harsh conditions.

2.2 Using the wrong type of tray leads to waste and safety risks

- Deploying regular trays in demanding settings like aquaculture, agriculture, or cold storage often results in breakage, warping, or slipping—posing potential hazards.

- Meanwhile, specialized plastic trays are purpose-built to overcome these issues, ensuring safer and more reliable storage and transport.

2.3 Material differences affect product lifespan

- Specialized trays use virgin HDPE or PP plastic, offering greater strength and extended usability.

- Regular trays are typically made from recycled or mixed plastics, which deteriorate more quickly—leading to frequent replacements and hidden costs.

2.4 Long-term economic efficiency depends on the initial choice

- Many users assume regular trays are more cost-effective. However, once you factor in repairs, replacements, and risk-related losses, investing in specialized plastic trays proves more economical in the long run.

- For enterprises, choosing the right trays from the start supports cash flow optimization and smoother operations.

2.5 Compliance with industrial hygiene and safety standards

- Industries such as seafood processing, agriculture, and export often require container solutions that meet strict hygiene regulations.

- Specialized plastic trays are designed with features like rounded edges, non-retentive surfaces, and antibacterial properties—standards that regular trays cannot meet.

3. Overview Comparison: Specialized Plastic Trays vs. Regular Plastic Trays

| Criteria |

Specialized Plastic Trays |

Regular Plastic Trays |

| Material Virgin |

HDPE or PP – durable, safe, and industry-compliant |

Recycled or mixed plastic – low durability, inconsistent quality |

| Load Capacity |

High load capacity (30–50kg); no warping when stacked |

Low load capacity (5–10kg); prone to cracking under heavy weight |

| Durability Over Time |

Lifespan of up to 5 years; UV-resistant and wear-resistant |

Short-term use; quickly degrades under moisture, sunlight, or water exposure |

| Usage Environment |

Optimized for aquaculture, agriculture, cold storage, industrial production lines |

Suitable for dry environments: offices, households |

| Design & Functionality |

Anti-slip edges, easy stacking, easy cleaning, ideal for transport and storage |

Basic design with limited functionality for storage and handling |

| Long-Term Cost Efficiency |

One-time investment; durable and cost-saving on replacement and repairs |

Low upfront cost but frequent replacements lead to hidden expenses |

| Technical Standards |

Meets hygiene and safety standards; suitable for international supply chains |

Does not meet stringent hygiene or technical requirements |

4. When Should You Use Specialized Plastic Trays?

4.1 In Harsh Environments with Constant Exposure to Water, Sunlight, or Wind

- In industries like aquaculture, fish farming, and seafood harvesting, trays must withstand saltwater, intense UV rays, and high humidity year-round.

- Specialized plastic trays offer UV resistance, corrosion protection, and long-lasting durability even in outdoor settings—making them a reliable solution.

4.2 When Regular Transport and Heavy Stacking Are Required

- If you frequently move trays using carts or forklifts and stack them high in warehouses, regular trays are likely to deform or break.

- Specialized plastic trays are reinforced with anti-slip designs, ensuring safety during stacking and transportation.

4.3 In Production Lines, Cold Storage, or Food Processing Areas

- For sectors requiring high hygiene standards—such as food, agricultural, or seafood exports—trays must be easy to clean and prevent contamination.

- Specialized plastic trays, made from virgin plastic, are non-toxic and certified under GMP or HACCP standards.

4.4 When You Aim to Maximize Long-Term Investment Efficiency

- While initial costs may be higher, their 5–7-year lifespan significantly reduces expenses related to maintenance, replacement, or damage due to incorrect usage.

- This makes them a smart investment for businesses looking to optimize operational costs over time.

4.5 When Tray Dimensions Must Align with Existing Storage Systems

- Large-scale farms, warehouses, or logistics businesses often need standardized tray sizes that fit into shelving, containers, or delivery vehicles.

- SIAM Brothers offers specialized plastic trays in various sizes and designs tailored to real-world demands, maximizing efficiency in storage and rotation.

The differences between specialized plastic trays and regular ones go far beyond material and durability—they directly impact operational efficiency, costs, and user safety.

If you're seeking a stable and long-term storage or transportation solution—especially in demanding environments like aquaculture, agriculture, or cold chains—then opting for specialized trays is no longer optional, but a strategic decision.

Contact SIAM Brothers Vietnam today for a free consultation and find the right specialized plastic tray tailored to your industry, needs, and budget.

We are committed to delivering high-quality, genuine products with nationwide shipping and on-site technical support.