Are you looking for a durable, high-load, and cost-effective buoyancy solution for your fish or shrimp cage farming system? In today’s fast-evolving aquaculture industry, which is shifting toward sustainable and high-efficiency practices, floating plastic buoys for aquaculture have become an essential component for professional farms. These buoys not only offer excellent stability on water surfaces but also feature superior construction using virgin HDPE plastic — a material that resists UV rays, corrosion, and is environmentally friendly.

So, what exactly are floating plastic buoys for aquaculture, why are they becoming increasingly popular, and how much does an HDPE buoy cost today?

Let’s explore everything you need to know in the detailed guide below from SIAM Brothers Vietnam — tailored for aquaculture practitioners seeking the best buoyancy solution for their cage farming systems.

1. What Are Floating Plastic Buoys for Aquaculture?

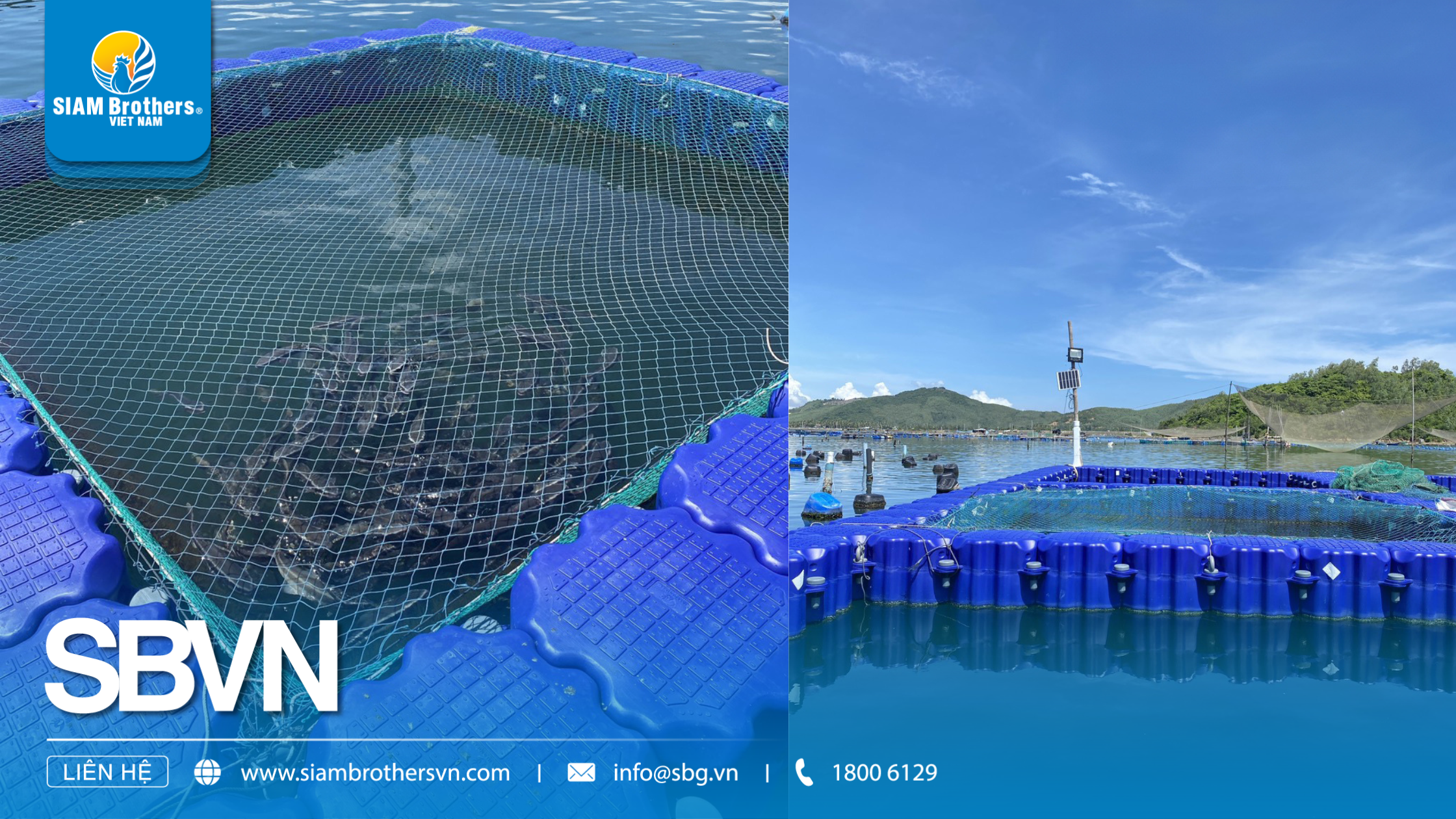

- Floating plastic buoys for aquaculture are buoy devices made from virgin HDPE or premium composite plastic, designed to resist UV radiation, corrosion, and withstand strong impacts.

- These buoys come in various shapes — cylindrical, square, or round — depending on specific usage, ensuring high stability and safety on the water surface.

- They are indispensable in large-scale aquaculture operations, especially in coastal areas, large lakes, or brackish water zones.

1.1 Role in Aquaculture Systems

- Stabilizing cage structures: Helps keep fish or shrimp cages level, preventing tilting due to waves and wind.

- Foundation for operations: Acts as a platform for movement, cage attachment, or support for auxiliary equipment.

- Maximizing investment efficiency: Reduces damage and maintenance costs compared to traditional foam or metal buoys.

1.2 Key Features of High-Quality Floating Plastic Buoys

- High-visibility colors (usually blue, orange, or black) for easy spotting in open water.

- Reusable and non-toxic, safe for aquatic life.

- Modular and easy to transport, install, and interconnect as needed.

Who Should Use These Buoys?

- Medium to large-scale fish/shrimp cage farm owners.

- Aquaculture cooperatives or enterprises investing in VietGAP or GlobalG.A.P. certified farming zones.

- Engineering and marine construction teams building industrial floating systems.

2. Structure of Floating Plastic Buoys – What Sets High-Quality Buoys Apart?

2.1 Standard Construction of Floating Plastic Buoys for Aquaculture

2.1.1 Outer Shell Material: Virgin HDPE Plastic

- UV-resistant, corrosion-proof, and designed to endure harsh marine conditions.

- Remains durable under long-term sun exposure without becoming brittle.

- Eco-friendly and non-toxic to aquatic organisms.

2.1.2 Fully Sealed Molded Design

- Single-piece construction with no seams — minimizing the risk of leaks or air loss.

- Provides stable and balanced buoyancy, even in rough water.

2.1.3 Shape Optimized for Interconnection

- Available in cylindrical, square, or curved designs based on specific applications.

- Built-in attachment points for ropes, hinges, or modular connectors — allowing flexible integration into large floating platforms.

2.1.4 Inner Core (Optional): Foam or Air Chamber

- Some premium models include a foam core for added flotation even if the outer shell is damaged.

- Lightweight for easy transport while maintaining high load capacity.

2.2 Key Differences Between High-Quality and Unregulated Buoys

Not all floating plastic buoys for aquaculture meet safety and performance standards — which is why choosing a trusted manufacturer like SIAM Brothers Vietnam is essential:

- Uniform plastic thickness for impact resistance and deformation prevention during transport.

- No recycled plastic used — ensuring a service life of over 10 years in real farming conditions.

- Certified quality control for buoyancy, load-bearing capacity, and airtightness.

- Easy maintenance and reusable, helping reduce long-term operational costs.

3. Functions and Real-World Applications of Floating Plastic Buoys in Aquaculture

3.1 Key Functions of Floating Plastic Buoys for Aquaculture

3.1.1 Maintain Buoyancy and Balance for Cage Systems

- Floating plastic buoys help stabilize entire cage structures, walkways, and work platforms on the water surface.

- They minimize the risk of tilting or sinking caused by waves or sudden changes in load.

3.1.2 Provide a Base for Supporting Aquaculture Equipment

- They serve as mounting platforms for nets, oxygen supply systems, automatic feeders, and water pipes.

- When used with durable ropes and connectors, buoys ensure a secure and stable structural foundation.

3.1.3 Maximize ROI Through Durability and Low Maintenance

- Designed to withstand saltwater, UV rays, and harsh weather conditions.

- They are non-absorbent, resistant to rot unlike wood, and more durable than foam buoys.

3.1.4 Support Efficient Farm Management and Operation

- Help organize farming areas systematically — defining cage zones, walkways, and technical sections, thus reducing labor needs.

- Can be flexibly expanded, upgraded, or dismantled based on production scale changes.

3.2 Real-World Applications in Vietnam’s Aquaculture Sector

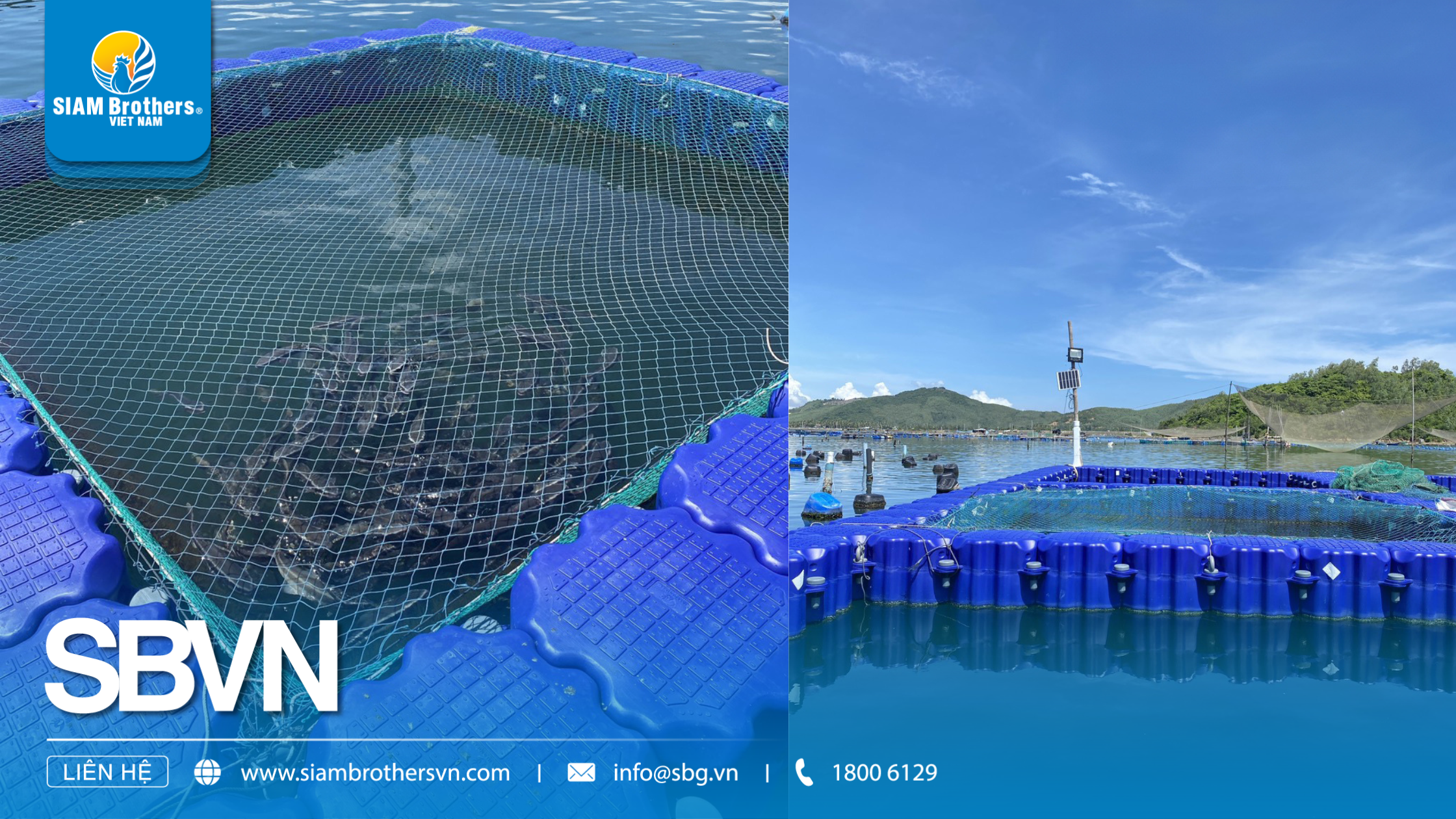

3.2.1 Offshore and Large Lake Fish Cage Farming

- Widely used in coastal provinces such as Khánh Hòa, Phú Yên, and Kiên Giang.

- Combined with frames and ropes to build strong, stable floating platforms.

3.2.2 Brackish Water Shrimp Farming and High-Value Fish Species

- Helps create separated rearing areas off the pond bottom, allowing better control of environmental conditions.

- Easy to clean, relocate, or adjust farming layouts as needed.

3.2.3 Outdoor RAS (Recirculating Aquaculture Systems)

- Used as the foundation for floating tanks or integrated technical modules.

- Supports mobile RAS farms with optimized system operation.

3.2.4 High-Tech Aquaculture Farms

- Compatible with IoT systems and water quality monitoring devices — HDPE buoys protect electronics from impacts.

- Meet export standards and traceability requirements.

4.1 Durability and Load Capacity

HDPE Buoys:

- High load-bearing capacity without becoming brittle, even after years of outdoor use.

- Resistant to corrosion in both saltwater and brackish environments.

Foam Buoys: Fragile, deteriorate over time, and absorb water, reducing buoyancy.

Metal Buoys: Strong but rust easily if not properly treated, leading to structural failure.

4.2 Safety in Long-Term Use

- HDPE floating plastic buoys for aquaculture are completely sealed, non-absorbent, and do not alter water quality.

- Foam buoys may release microplastics as they degrade, harming aquatic ecosystems.

- Metal buoys are heavy and pose structural risks when corroded.

4.3 Reusability and Maintenance

- HDPE buoys are easy to clean and reusable over many years without performance loss.

- Foam buoys often need replacing each season — increasing operating costs.

- Metal buoys require periodic rust-proof coatings and inspections — adding to maintenance expenses.

4.4 Weight and Installation

- HDPE buoys are lightweight, easy to move and install — suitable for both coastal and inland waters.

- Foam buoys are also light but less stable and more prone to drifting in strong waves.

- Metal buoys are heavy, costly to transport, and require larger labor forces for deployment.

4.5 Aesthetic and System Integration

- HDPE buoys come in various colors (blue, orange, black) and shapes — harmonizing with cages, ropes, and platforms.

- Foam and metal buoys are not typically designed for system integration, making expansion and standardization difficult.

Choosing the Right Buoy for Long-Term Aquaculture Success

If you’re investing in a comprehensive aquaculture system and aiming for long-term cost efficiency, HDPE floating plastic buoys for aquaculture are the most reliable option:

- Reduce maintenance and replacement costs over many years of use.

- Safe and environmentally friendly for aquatic species and water quality.

- Professionally engineered to suit various farming models — from marine cage fish farming to high-tech aquaculture operations.

Source: SIAM Brothers Vietnam

Contact us:

Address: 5th floor, VRG Building, 177 Hai Ba Trung Street., Vo Thi Sau Ward, District. 12, Ho Chi Minh City, Vietnam

Tel: (+84) 28 38 912 889

Hotline: 1800 6129

Facebook: www.facebook.com/siambrothersvn

Email: info@sbg.vn

YouTube: youtube.com/@siambrothersvietnam1728

X: x.com/sbvnjsc

OA Zalo: zalo.me/1402339229697925373

App SBVN ID: