In many industries, from maritime and construction to agriculture and recreation, ropes play a crucial role. Among the many types of ropes available, 4-strand ropes have garnered attention for their unique structure and versatility. But why should you choose a 4-strand rope? What are its specific benefits and applications? In this article, SIAM Brothers Vietnam will delve into the characteristics that set 4-strand ropes apart, the advantages they offer, and the industries where they are most commonly used.

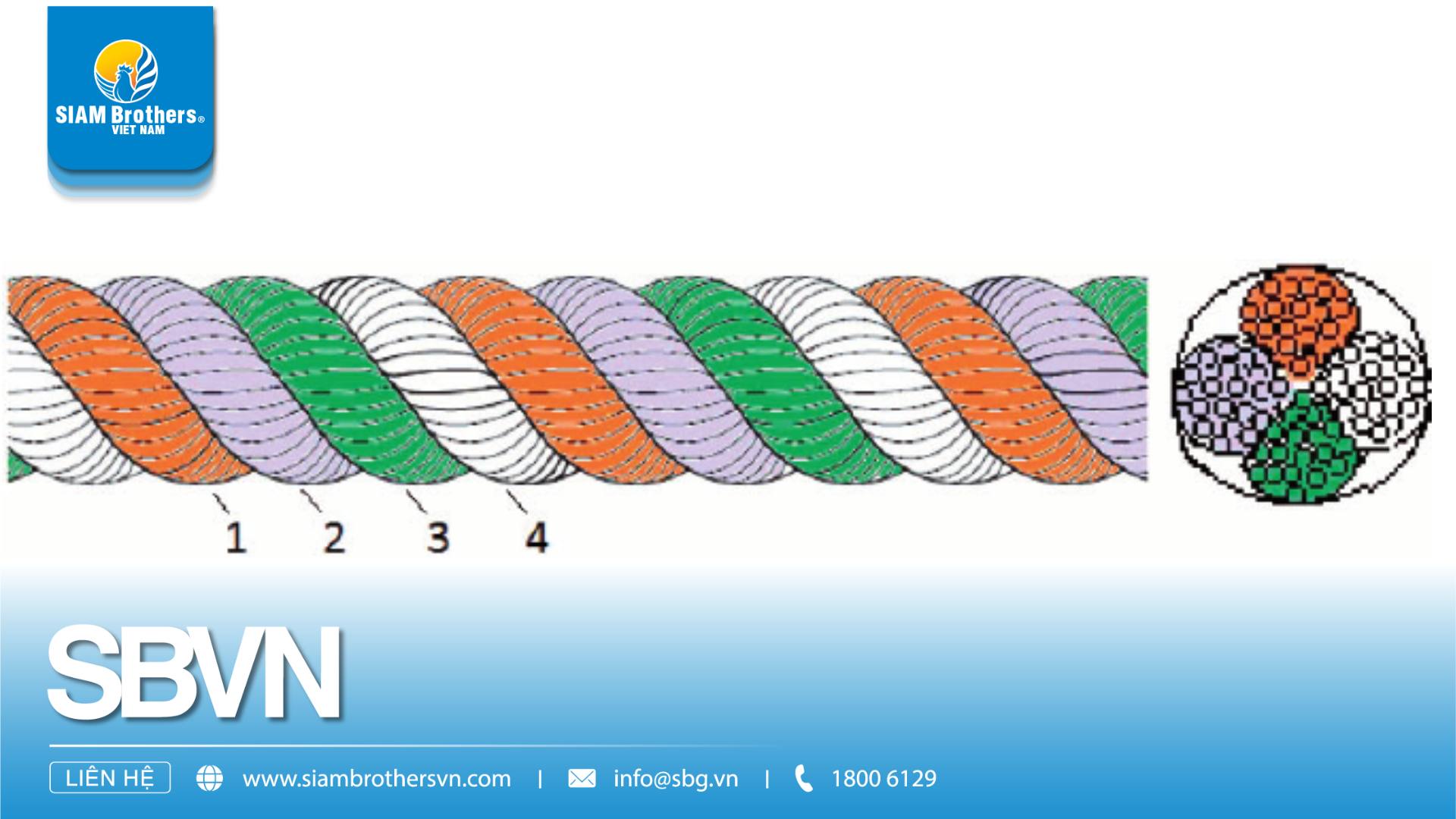

A four-strand rope structure showing the yarns and their cross-section. / Cre: researchgate

A 4-strand rope is a type of rope construction where four individual strands are twisted together. While 3-strand ropes are more common, the additional strand in a 4-strand rope provides improved balance and strength, making it suitable for demanding applications. Typically made from materials like nylon, polyester, polypropylene, or high-performance fibers like Dyneema, these ropes are designed for durability, flexibility, and resistance to environmental factors.

The extra strand also improves the overall wear and tear resistance, offering a more balanced load distribution across the rope. This design makes it especially useful in situations where long-term durability and strength are required.

Find more related article

THE PRACTICAL BENEFITS OF 3-STRAND ROPES FOR MARITIME AND OUTDOOR USE

4-strand rope enhance better strength

The primary benefit of a 4-strand rope lies in its increased strength. The additional strand enhances the tensile strength of the rope, allowing it to handle heavier loads. Compared to 3-strand ropes, which are commonly used in lighter-duty applications, 4-strand ropes are better suited for heavy-duty tasks where more force is applied, such as hoisting, towing, or anchoring.

For industries like construction and maritime, where safety and performance are paramount, using a stronger rope translates to fewer accidents, lower maintenance costs, and greater overall efficiency.

Ensuring Stability and Load Distribution / Cre: xmonstersafety

Find more: Is Polypropylene Rope UV Resistant?

With four strands, the rope offers better balance and stability. This reduced chance of twisting or kinking makes it easier to handle and more reliable for applications that require precision. In marine and industrial environments, where ropes are often subjected to dynamic movements, the ability of a 4-strand rope to remain stable and untangled is crucial.

This stability also makes 4-strand ropes easier to store and transport, as they are less likely to develop twists that need to be corrected before use.

Anti-abrasion in seawater environment

A rope’s ability to withstand friction and wear is key to its longevity. The 4-strand design offers greater surface area and thicker cross-sections, which translates to improved abrasion resistance. Whether dragging the rope across rough surfaces or exposing it to harsh weather conditions, 4-strand ropes can endure more punishment before showing signs of wear.

Easy to knot in climbing or camping scenarios

Find more: 8-Strand Rope: The Perfect Choice for Heavy-Duty Work

Despite its strength, a 4-strand rope retains a high level of flexibility. This flexibility is essential for applications that require tying complex knots, rigging, or making secure loops. The rope’s adaptability in both heavy-duty and lighter tasks ensures that it can be used across various industries without sacrificing performance.

For example, in climbing or camping scenarios, a flexible rope that can be easily knotted is vital for safety and utility.

saving costs on materials and reducing downtime / Cre: iconscout

Although a 4-strand rope may have a higher initial cost than a 3-strand rope, its enhanced durability and strength offer greater value over time. The need for frequent replacements is minimized, saving costs on materials and reducing downtime for industries reliant on reliable equipment.

In sectors like construction, where delays can lead to significant financial losses, the long-lasting nature of a 4-strand rope makes it a cost-effective solution.

Applications in maritime industry

Find more: Simple and Easy DIY Tips with Rope

The maritime industry relies heavily on ropes for mooring, towing, and anchoring ships. A 4-strand rope is particularly suited for these applications due to its strength, stability, and resistance to harsh marine environments. The ability to withstand saltwater corrosion and UV exposure makes 4-strand ropes a preferred choice for sailors and shipping companies.

Applications in agriculture

In agriculture, ropes are used for securing loads, tying plants, and hoisting heavy equipment. A 4-strand rope’s superior strength and resistance to wear make it ideal for securing loads during transport or tying up large crops like durians or timber.

Applications in construction / Cre: magicglass

Construction sites are demanding environments that require reliable equipment. Whether used for lifting heavy materials or securing scaffolding, 4-strand ropes provide the strength and durability needed for these challenging tasks. Their flexibility also allows workers to tie and adjust them quickly without compromising safety.

a 4-strand rope is used for outdoor activity

In recreational activities such as climbing, camping, or sailing, a 4-strand rope offers both safety and flexibility. Its resistance to environmental factors makes it ideal for outdoor adventures, where ropes are exposed to moisture, friction, and constant tension. Whether used for securing tents, climbing cliffs, or towing boats, 4-strand ropes ensure reliable performance.

Selecting the right 4-strand rope for your needs depends on several factors:

Choosing a 4-strands rope depends on the demand / Cre: indiamart

Different materials offer distinct advantages. Nylon, for instance, is known for its elasticity, making it a good choice for dynamic loads. Polyester, on the other hand, is resistant to UV rays and moisture, making it suitable for outdoor applications. Polypropylene is lightweight and resistant to chemicals, while Dyneema offers unmatched strength for heavy-duty applications.

Find more related article

Is Polypropylene Rope UV Resistant?

What is the Difference Between PP Rope and Nylon Rope?

Consider using the product in different environments

Consider the conditions the rope will be exposed to. For marine use, a rope that resists saltwater and UV damage is critical. In industrial settings, a rope that can withstand friction and heavy loads without breaking down is essential. Evaluating these factors helps in making the right choice for long-term performance.

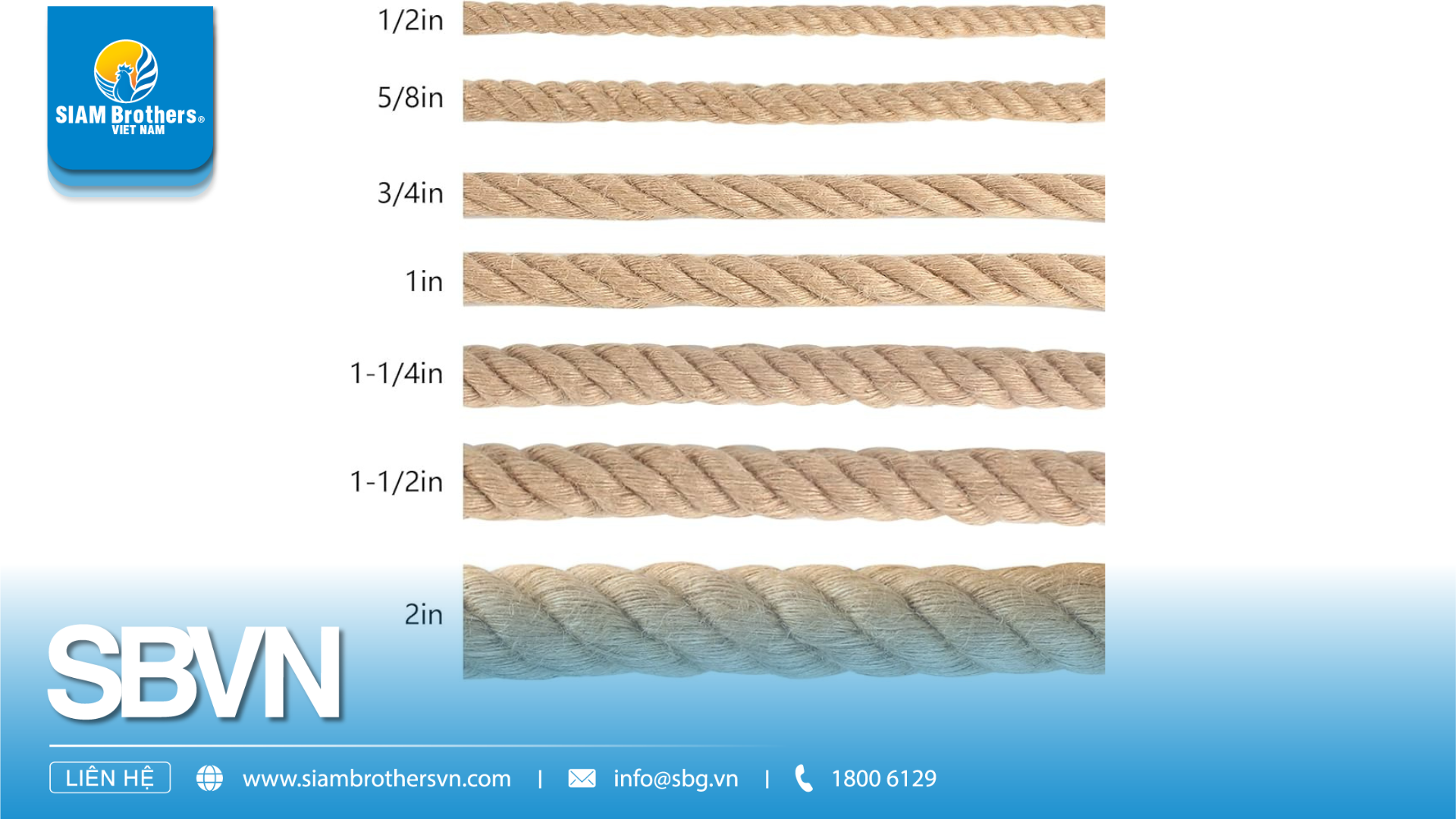

Size and Diameter

Find more: Where to buy rope in Ho Chi Minh City?

The size and diameter of the rope determine its load-bearing capacity. A thicker rope can handle more weight, but it may also be less flexible. For heavy-duty applications, a thicker rope is usually preferred, while smaller ropes are better for recreational or light industrial use.

To ensure the longevity of your 4-strand rope, proper maintenance is essential:

Regular Inspections: Check for signs of wear and tear, including fraying, cuts, or broken strands.

Cleaning: Remove dirt, salt, or chemicals by rinsing the rope with fresh water. Avoid harsh detergents that could degrade the fibers.

Storage: Store the rope in a cool, dry place, away from direct sunlight and moisture, to prevent damage from UV rays or mold.

Replacement: Even the most durable ropes will need replacement eventually. If the rope shows significant wear or has lost its flexibility, it’s time for a new one.

A 4-strand rope offers significant advantages in terms of strength, stability, and durability, making it a versatile choice across multiple industries. From the maritime and construction sectors to agriculture and recreational activities, the benefits of using a 4-strand rope are clear. By understanding its applications and choosing the right material, size, and maintenance practices, you can ensure optimal performance for your needs.

Whether you’re securing a load, anchoring a ship, or hoisting heavy equipment, a 4-strand rope is a reliable, cost-effective solution that guarantees safety and efficiency. For high-quality 4-strand ropes designed to meet the toughest demands, contact SIAM Brothers Vietnam. With decades of expertise and commitment to the excellence rope manufacturing sector, we provide the best rope solutions for every industry. Contact us today to find the perfect fit for your business needs.

Cre: SIAM Brothers Vietnam

Contact us:

Address: 5th floor, VRG Building, 177 Hai Ba Trung Str., Vo Thi Sau Ward, Disc. 12, Ho Chi Minh City, Vietnam

Tel: (+84) 28 38 912 889

Hotline: 1800 6129

Fanpage: facebook.com/siambrothersvn

Email: info@sbg.vn

Youtube: youtube.com/@siambrothersvietnam1728

X: https://x.com/sbvnjsc

OA Zalo: zalo.me/1402339229697925373

App SBVN ID:

CHPlay: https://bit.ly/SBVNID-Android

Appstore: https://bit.ly/SBVNID-iOS