Net ropes are a crucial component of fishing gear, particularly in nearshore fishing activities. Choosing the right type of net rope not only improves the durability of the net but also enhances fishing efficiency and reduces costs for fishermen. This article offers an in-depth examination of the features, types, and selection criteria for selecting suitable net ropes in coastal environments.

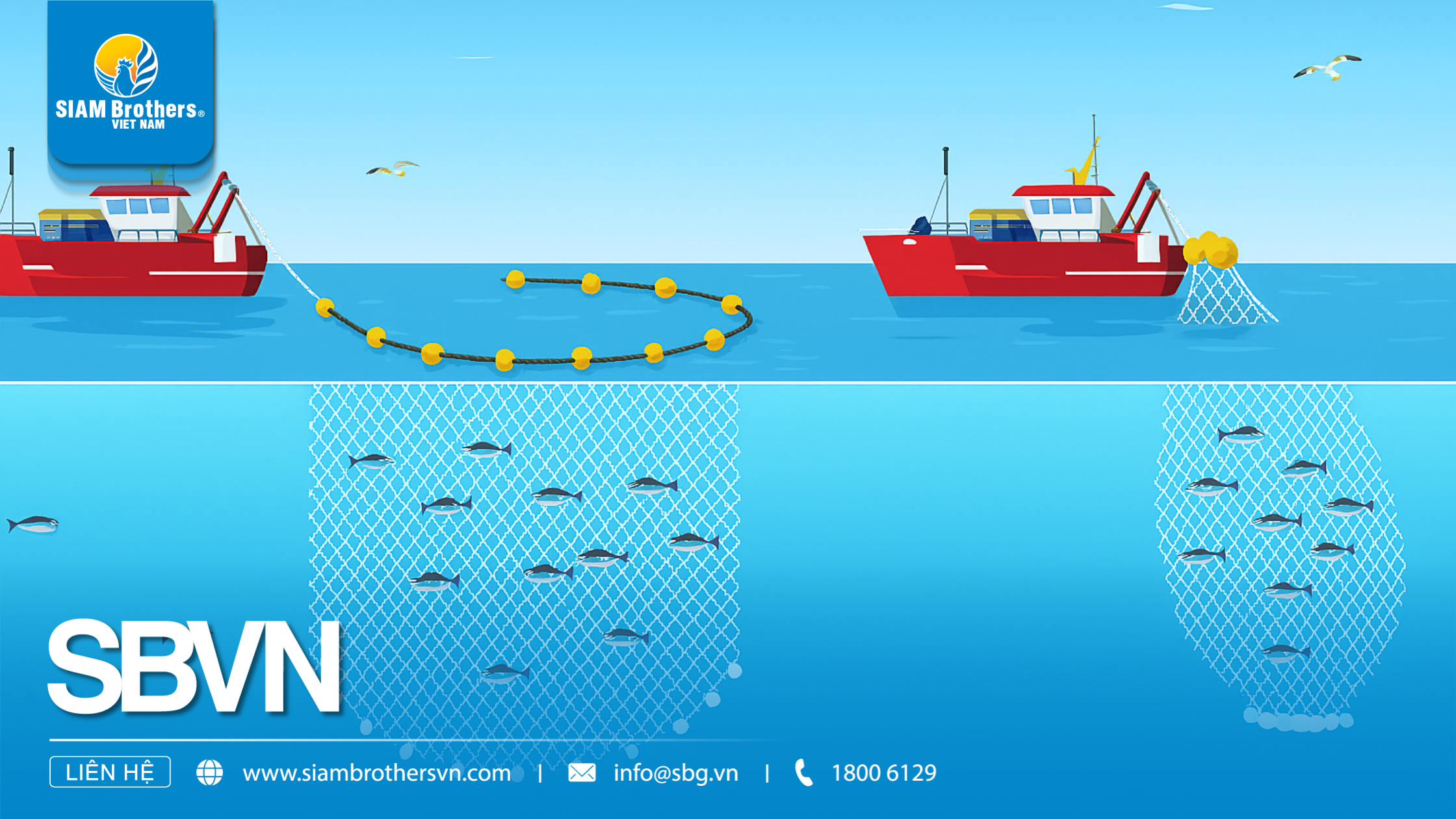

Illustration of Net Rope – Source: SIAM Brothers Vietnam

Net ropes are used to secure the upper and lower edges of a fishing net, commonly referred to as the floatline and leadline. These ropes help stabilize the net’s shape and ensure that the fishing operation is both effective and safe. They form the core connection between the various components of fishing gear, enabling the entire system to function smoothly in coastal marine conditions.

Net ropes are typically sewn, tied, or braided tightly into the edges of fishing nets. Floats are attached to the top rope (floatline) to keep the net suspended, while lead weights are added to the bottom rope (leadline) to help it sink and open up properly during fishing. This construction is beneficial in nearshore areas with strong waves and variable terrain.

Net ropes endure the greatest tension when the net is deployed and retrieved. If the rope lacks sufficient strength, the net may tear or lose its shape, leading to operational setbacks and financial loss. Investing in high-quality net ropes is therefore essential for stable and productive nearshore fishing.

Nearshore fishing takes place in coastal areas where natural conditions can be particularly challenging, such as strong currents, rocky seabeds, and sudden weather changes. In these environments, high-quality net ropes are essential for several reasons.

First, they provide the durability and tensile strength needed to withstand the physical forces of repeated casting, hauling, and occasional snagging on underwater obstacles. Low-grade ropes may fray or break easily, risking the loss of gear and catch.

Second, high-quality ropes resist UV radiation and saltwater corrosion, both of which are unavoidable in coastal fishing. This resistance significantly extends the lifespan of the rope and reduces the frequency of replacement, helping fishermen lower operational costs.

Third, better-quality ropes maintain knot integrity and are easier to handle, floating if needed, or sinking predictably when paired with weights, allowing for smoother and more efficient net deployment and retrieval. All of these factors contribute directly to catching success and safety, which is why experienced fishermen prioritize using superior rope materials for their nearshore operations.

Historically, net ropes were made from natural fibers like jute, sisal, or coconut coir, which degrade quickly and are suitable only for small-scale operations. Today, most net ropes are made from synthetic fibers such as polypropylene (PP), polyethylene (PE), or polyamide (PA - nylon), known for their high tensile strength, water resistance, and UV protection—ideal for harsh marine environments.

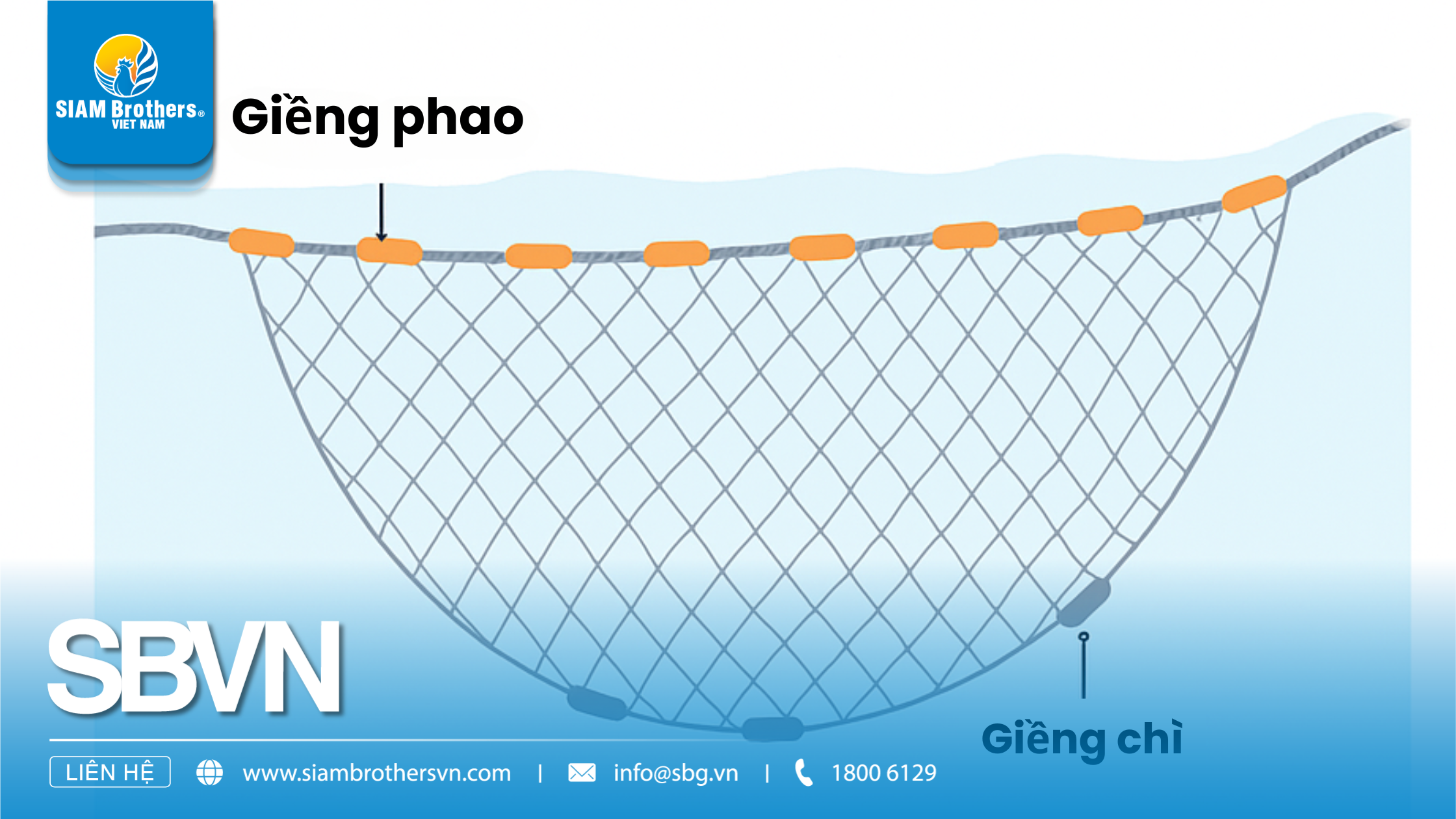

Illustration of Net Rope – Source: SIAM Brothers Vietnam

These ropes are typically twisted into three or four strands. Multi-strand ropes offer greater durability and reduce tangling during handling, critical features for small fishing vessels operating in tight, dynamic conditions.

Illustration of Net Rope – Source: SIAM Brothers Vietnam

Functionally, net ropes are divided into floatlines and leadlines. Floatlines are attached to the upper edge of the net to keep it afloat, while leadlines hold the lower edge down, allowing the net to maintain its intended opening.

For nearshore use, the net rope should be at least 3mm in diameter and have a tensile strength exceeding 150kgf. This ensures it can withstand pressure from currents, wave action, or contact with underwater obstacles.

High-quality ropes feature tightly braided exteriors that resist abrasion from sand, rocks, or boat surfaces. This reduces wear and extends the lifespan of the fishing gear.

Exposure to sunlight and saltwater requires ropes with built-in UV stabilizers and salt-resistant properties. These features prevent the rope from becoming brittle or decaying over time.

Lightweight ropes are easier to cast and retrieve, especially from small boats. PP and PE ropes naturally float, making them ideal for use as floatlines.

Durable ropes can last for 2–3 fishing seasons without significant degradation. This long lifespan reduces replacement costs and labor for repairs.

Cleaning Net Rope – Source: SIAM Brothers Vietnam

Fishermen should inspect ropes after every fishing trip. Signs of wear, fraying, or weakness should be addressed promptly to avoid failure during future use.

Ropes should be rinsed with fresh water after each trip to remove salt and sand, helping maintain flexibility and prevent deterioration.

Store ropes in a dry, shaded area away from chemicals and direct sunlight. Coiling ropes properly and avoiding heavy pressure preserves their structure.

Onshore fishing net rope - Source: SIAM Brothers Vietnam

With over 30 years of experience serving Vietnam’s fishing industry, Siam Brothers Vietnam is a leading name in rope and fishing gear manufacturing. Their onshore fishing net rope product line is engineered specifically for coastal fishing demands.

This rope is made from premium PP and PE fibers with UV protection additives, offering durability in sunlight and saltwater conditions. It boasts 1.5 times the strength of conventional ropes, floats on water, and secures knots effectively—ideal for coastal fishing vessels.

Available in diameters starting from 3mm, the ropes are offered in coils of 180m, 220m, and 1000m. Standard colors include black and moss green, with customization available upon request.

The onshore fishing net rope is suitable for gillnets, seine nets, and trawl nets used nearshore. It is also well-suited for anchoring, net rigging, boat mooring, and other versatile marine applications—empowering fishermen to operate confidently in demanding conditions.

Read more: What is Marine Rope? How to Choose the Right Type for Effective and Safe Use in the Fishing Industry

Source: SIAM Brothers Vietnam

Contact us:

Address: 5th floor, VRG Building, 177 Hai Ba Trung Street., Vo Thi Sau Ward, District. 12, Ho Chi Minh City, Vietnam

Tel: (+84) 28 38 912 889

Hotline: 1800 6129

Facebook: www.facebook.com/siambrothersvn

Email: info@sbg.vn

YouTube: youtube.com/@siambrothersvietnam1728

OA Zalo: zalo.me/1402339229697925373

App SBVN ID:

CHPlay: https://bit.ly/SBVNID-Android

Appstore: https://bit.ly/SBVNID-iOS